Mining & Aggregates

A drone in the mining industry provides accurate and comprehensive information on the condition of quarries and mines in a short time, thus increasing the efficiency of large mines and quarries.

What is a drone mining survey?

Mining drone inspection means that a drone equipped with a downward RGB camera, LiDAR, or other measurement sensors captures images from different points of the open-pit mine or quarry. These images or LiDAR point cloud data are then processed by comprehensive and professional photogrammetry software to form geotagged 3D maps, Digital Elevation Models (DEM), Digital Terrain Models (DTM), Digital Surface Models (DSM), etc. for detailed analysis by operators.

Benefits of using drone in mining

Drone surveying is being used in more and more mining operations. They enable more efficient and accurate data collection compared to traditional methods. Let's check the benefits of using drone in mining in detail:

Improve safety

It's very dangerous that surveyors to collect visual data on the state of potentially unstable areas of the mine, such as high walls, crests, slugs, and blast points. Using drones means fewer people are exposed to these hazards.

High accuracy

Drones give a complete rendering of greater precision. A LiDAR drone can fly lower than the planes generally used for the acquisition of this data, which makes it possible to optimize the number of reference points and to offer more high accuracy in the data.

Low operating costs

The operating costs associated with drones are lower than the costs of traditional survey methods. The drone applications are unlimited and exploitable throughout the process (exploration, development, and operations), not to mention, not to mention, the rapid assessment of dangers.

Increase worker efficiency

Mining companies can use high-resolution images captured by drones to analyze current routes and see how they can be optimized for better efficiency. And then share the status of an ongoing operation with stakeholders.

How drones are used in mining?

Listed below are the key trends in how commercial drones are being utilized or will be used across the mining industry.

Mining mapping and surveying

In the early exploration, it is possible to apply them to reconnoiter the topography in areas that cannot be easily reached due to their geography. In this way, its use helps quantify surfaces and volumes and also makes a superficial recognition of possible outcrops when this occurs in mineralized areas that may indicate a mineral deposit. This improves recognition at scales of hundreds of hectares in areas of difficult access.

Stockpile management

The UAV acquires a highly accurate digital surface model and digital orthophotography by flying at low altitude, which, when combined with the DoD algorithm, quickly calculates the volumetric change in the mine's active reserves, multiplied by the mine's average ore content, average ore weight, and average grade to obtain the change in the stockpile.

Mine or quarry monitoring

Other applications in mining operations that are being executed are to monitor stability risk areas, such as slopes, but also in old dumps, and abandoned tailings. With this, possible cracks or faults can be identified that may be indications of possible landslides.

Assessment before and after drilling or blasting

By using the 3D mapping drone in mining to help reconstruct a 3D model of the area to be blasted or drilled, operators can make a design more adjusted to the topography, improving the fragmentation process in the mine and reducing ore spills. Meanwhile, this data also allows you to better manage resources, such as the number of explosives and trucks required.

Mining exploration

In underground mining, its use is also being evaluated in recognition of the exploitation of mansions, shafts, unstable areas, and galleries at risk of landslides, among others. However, the difficulty lies in the positioning of the drones, since there is no access to reference points, as is the case in open-pit mining. However, applications are being developed to position themselves through sensors.

Mining restoration planning

The development of mine restoration and management plans is based on high-precision spatial information of mine topography and geomorphology. The establishment of a three-dimensional spatial model by combining UAV inclined photogrammetry technology and GIS not only can obtain highly accurate spatial information but also can more realistically reflect the actual geomorphology of the flight area, which greatly reduces the difficulty of surveying.

Water and air quality monitoring

The drones are equipped with gas detectors and imaging spectrometers specifically designed to detect signs of Acid Mine Drainage (AMD) in the atmosphere and water quality around the mine. These advanced sensors, coupled with automated collection and analysis processes, allow for continuous monitoring of the environment. By utilizing drones for environmental monitoring, we can keep a close eye on the mine's environmental data and take proactive steps to protect the surrounding ecosystem from potential AMD contamination.

The drones are equipped with gas detectors and imaging spectrometers to detect the atmosphere and water quality around the mine, and the process of collection and analysis is automated. The use of drones for environmental monitoring is a great way of keeping track of the mine's environmental data and protecting the environment.

Coal fire monitoring

The storage of large quantities of coal at mines can easily lead to a high risk of fire. Spontaneous ignition most often occurs in the lower layers of the storage pile due to the elevated temperature of the material. Continuous drone surveillance of the surface layer with thermal cameras can detect hot spots early and avoid coal fires.

Mine Reclamation

Drones streamline mine reclamation by offering quick and precise aerial surveys, capturing data to create 3D models that monitor material movement and track reclamation progress. They assist in planning backfill, evaluating water quality, and assessing vegetation growth. This real-time data helps improve reclamation accuracy, ensures environmental compliance, and simplifies communication with stakeholders, making the entire process more efficient and cost-effective.

What kinds of maps can you expect from mining drones?

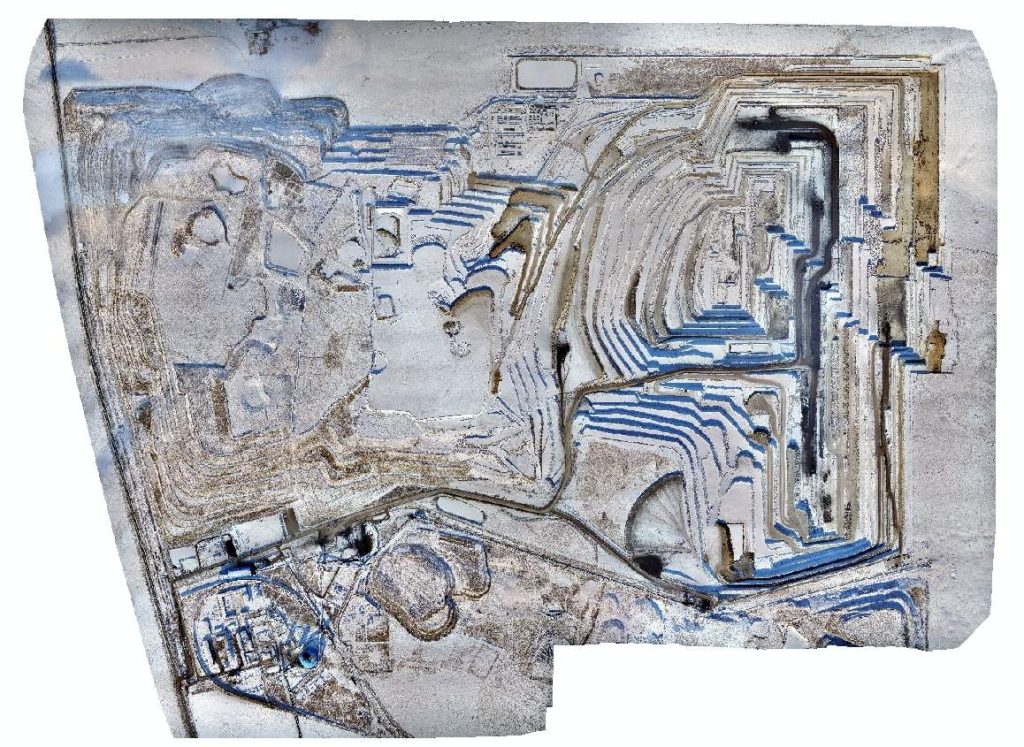

Orthomosaic maps

They allow detailed visual monitoring of the state of the quarry, measurements of surfaces and distances, etc.

The CW-25E with JoLiDAR-LR22S produced an accurate digital orthophoto model for the Baorixile open-pit mine.

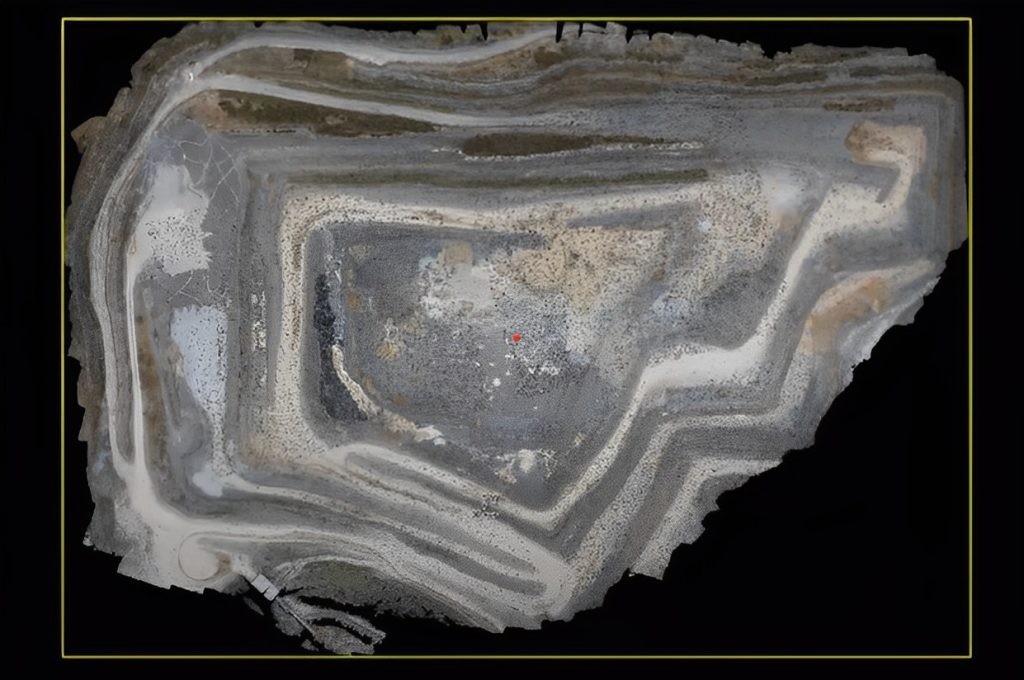

3D model

A 3D reconstruction, in addition to containing high-detail three-dimensional information, is a very powerful way of explaining the project to people with fewer skills.

3D point cloud

Point clouds are collections of three-dimensional coordinates. They have very high detail (millions of points) compared to traditional measurement methods, and they are useful in volume estimation and simulation programs.

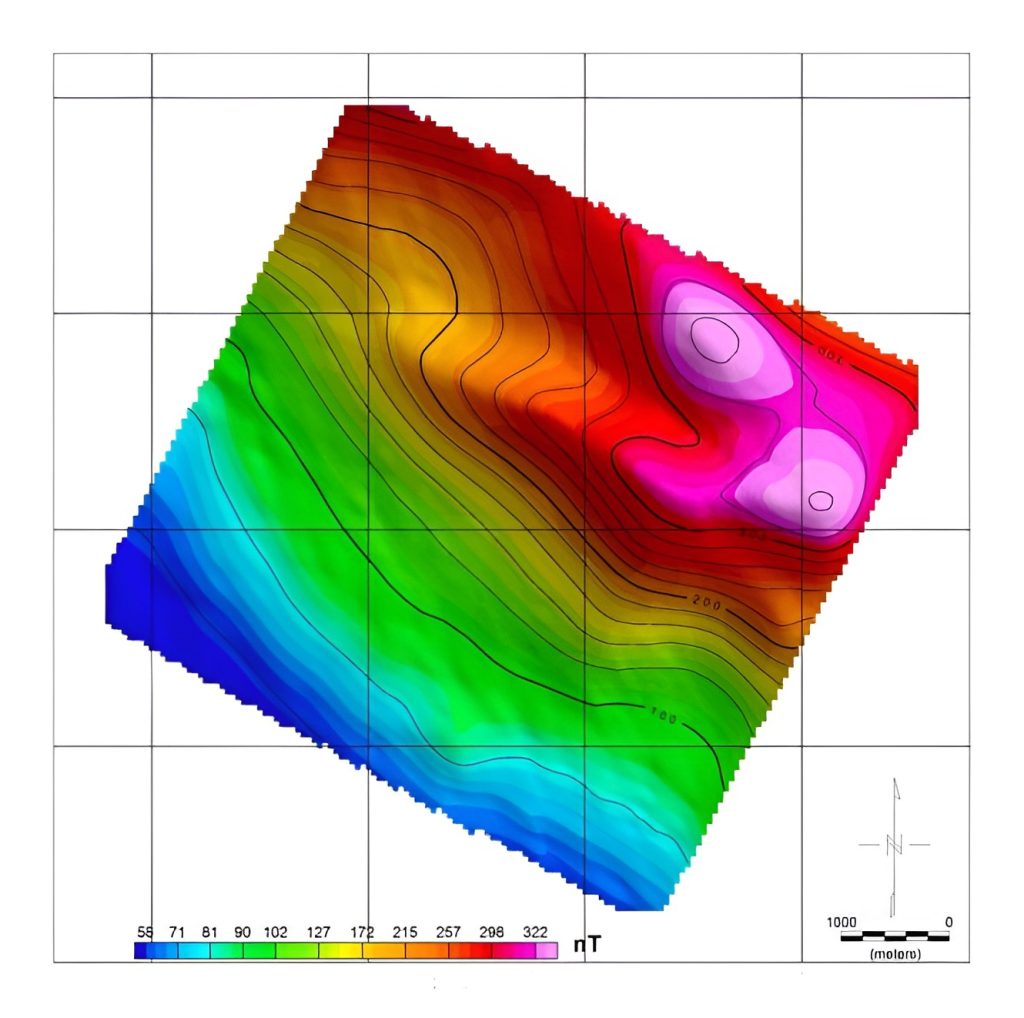

Aeromagnetic map

By measuring the strength of the Earth's natural magnetic field, the drone magnetic surveying constructs a map representing the changing properties of magnetic rocks and a 2D or 3D model of the geology of the Earth's crust. These models are aeromagnetic maps, which can be used for mining exploration.

What are the best drones for the mining industry?

JOUAV drones are the best drones created especially for mapping and surveying services in the mining industry. It is a fixed-wing drone with vertical take-off and landing capabilities and a number of impressive features.

Take off and land vertically (VTOL)

JOUAV drones combine the advantages of a fixed drone and a multi-rotor drone. Unlike other fixed-wing drones that need to land over wide areas and soft terrain, JOUAV drones can take off from confined areas and land smoothly in gravel and open pits. In addition, different from other multi-rotor aircraft, the JOUAV VTOL drone can fly faster and has a longer flight time.

61.0 megapixels/down to 1cm (1.2")

With a 61.0 megapixels full-frame camera, JOUAV drones can fly at a high altitude over a deep pit and still deliver low GSD images. The drones have a built-in multi-frequency PPK GNSS receiver that provides best-in-class absolute horizontal accuracy of up to 1 cm (0.4") and vertical accuracy of up to 3cm (1.18").

Fully autonomous flight

After planning the route, JOUAV drones can now fly autonomously at remarkably high speeds, while navigating unpredictable obstacles using their onboard sensors. In our test, JOUAV drones can keep speeds of up to 60~100km/s without crashing into trees, walls, or obstacles.

Best payload solutions for mining

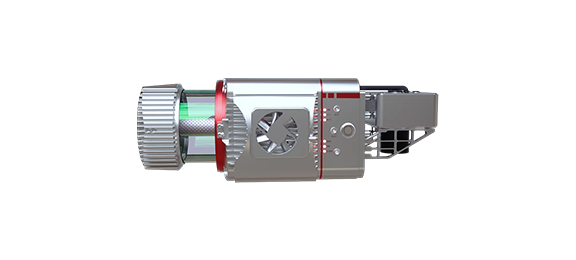

LiDAR: mining mapping and surveying

JoLiDAR-LR22S is the best long-range and high-precision UAV LiDAR solution for mining. With a built-in high-precision GNSS INS board and laser scanner, the sensor achieves elevation accuracy of less than 5cm, plane accuracy of less than 8cm, and distance of up to 1854m, meeting the needs of engineering measurement. JoLiDAR can sort data quickly, which greatly increases the speed of data processing and enables you to complete projects in the shortest possible time with little interruption.

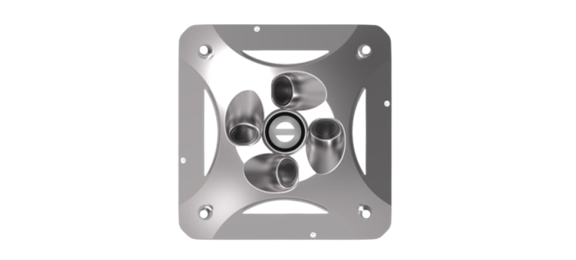

Oblique camera: mining mapping and surveying

Integrating 120 megapixels half-frame five lenses, the CA500R Series Oblique Camera collects oblique imagery, which can not only truly reflect the ground conditions and obtain multi-directional texture information with high precision, but also generate real-world 3D models through advanced positioning, fusion, modeling, and other technologies.

Gimbal Camera: Real-time mine monitoring

The MG-120E Gimbal Camera is the best surveillance drone camera that combines an optical zoom camera with a high-precision thermal image sensor. Its 30x optical zoom camera identifies details of equipment, buildings, and structures within 2km. 640*512 resolution thermal sensor allows monitoring of coal mines at night or in low visibility and also identifies potential problems that are invisible to the naked eye.

Feel free to contact JOUAV. What we can help you: