Inspecting 52km of Powerlines for China Southern Power Grid in 2hrs

China Southern Power Grid is revolutionizing the way power line inspections are conducted in the country with drone-based inspections. In the past, the state-owned enterprise relied on foot patrols, which were slow, tedious, and lacked accuracy. However, in 2018, they acquired JOUAV's CW-30 LiDAR, CW-10, CW-15, CW-25, and CW-25E LiDAR and monitoring system to help inspect power lines more effectively. This system has enabled the company to inspect hundreds of thousands of kilometers of power lines.

Members of China Southern Power Grid responsible for this powerline corridor inspection

Recently, the company conducted a pilot project to test the effectiveness of UAV inspections in areas of high altitude and heavy ice. Using the JOUAV CW-25E drone, they were able to collect LiDAR data for 52 km of power lines in just two hours.

Challenges

The project faced several challenges. Firstly, the mission was carried out in a winter environment with temperatures as low as -4°C and strong wind gusts. These conditions required the UAV to have a high endurance for low temperatures. Secondly, the power line was located in a mountainous area with high altitudes and large terrain differences. The complex terrain made it difficult for the UAV's communication signal to reach the control team. Thirdly, the project had a high-efficiency requirement, with a wide inspection area and a tight deadline. Finally, the inspection task was performed after 7:00 p.m., limiting the line of sight for the team.

Mission

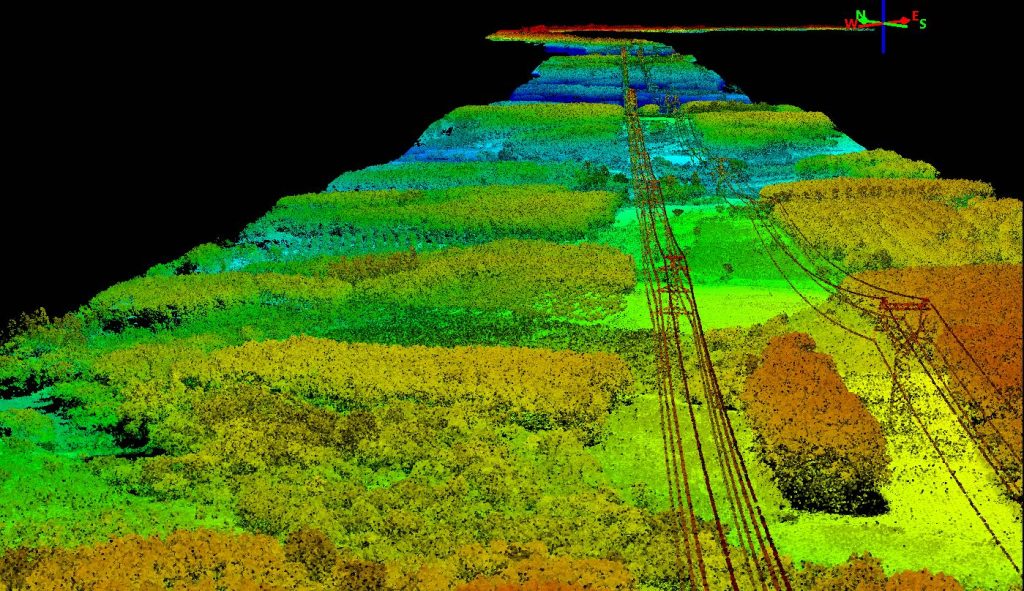

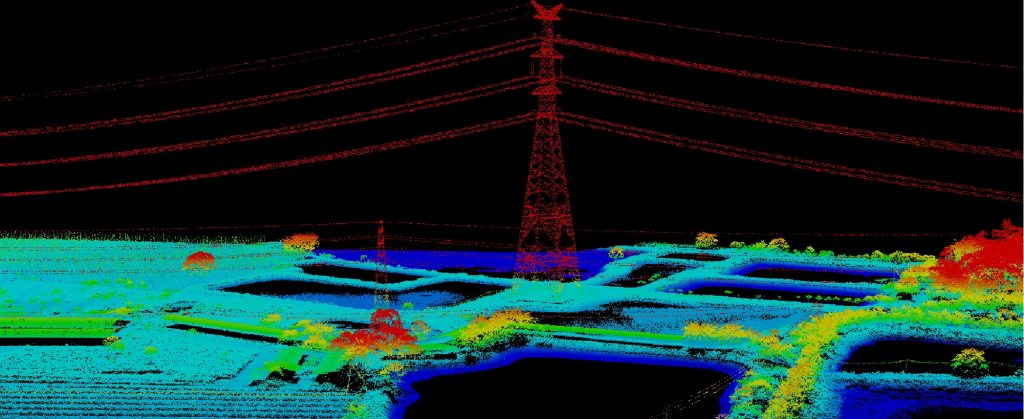

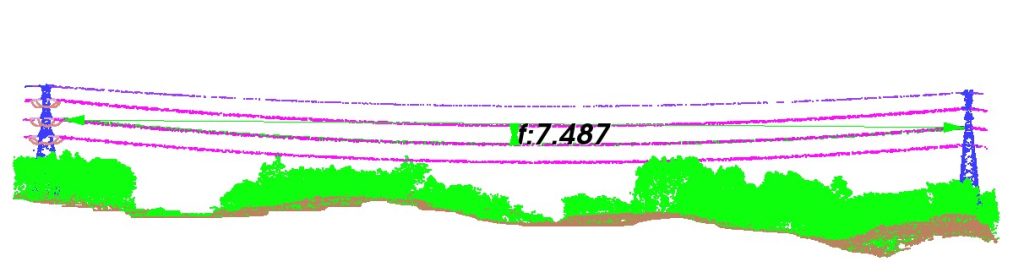

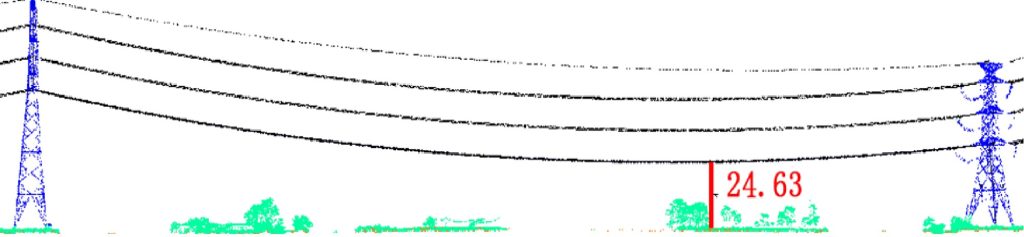

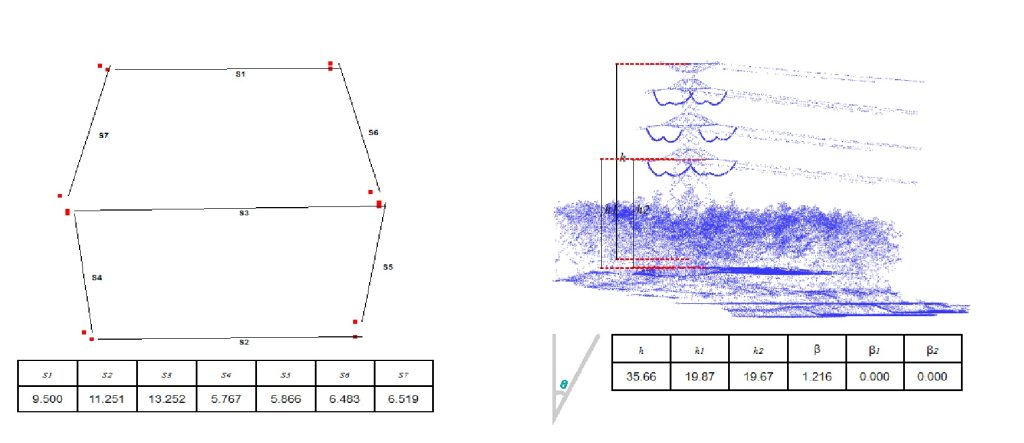

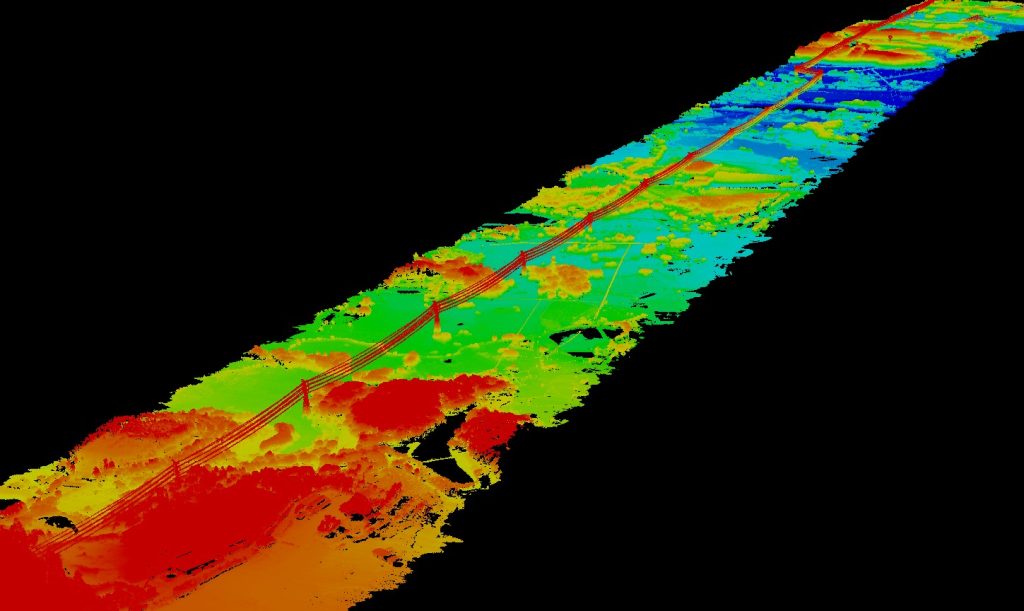

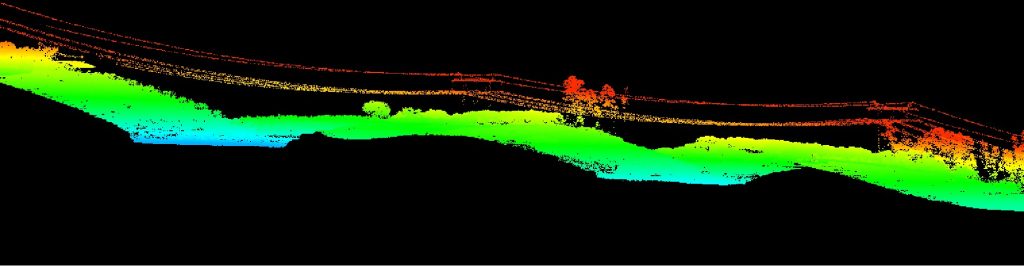

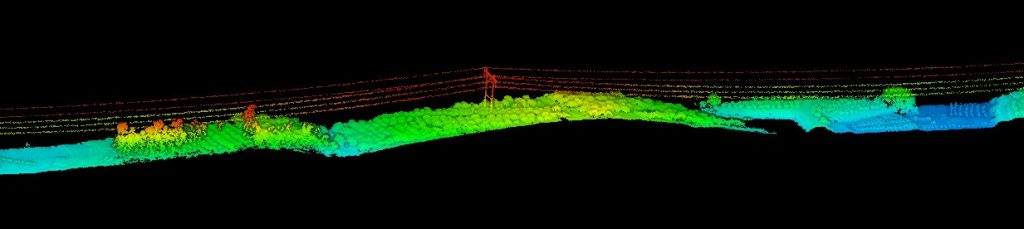

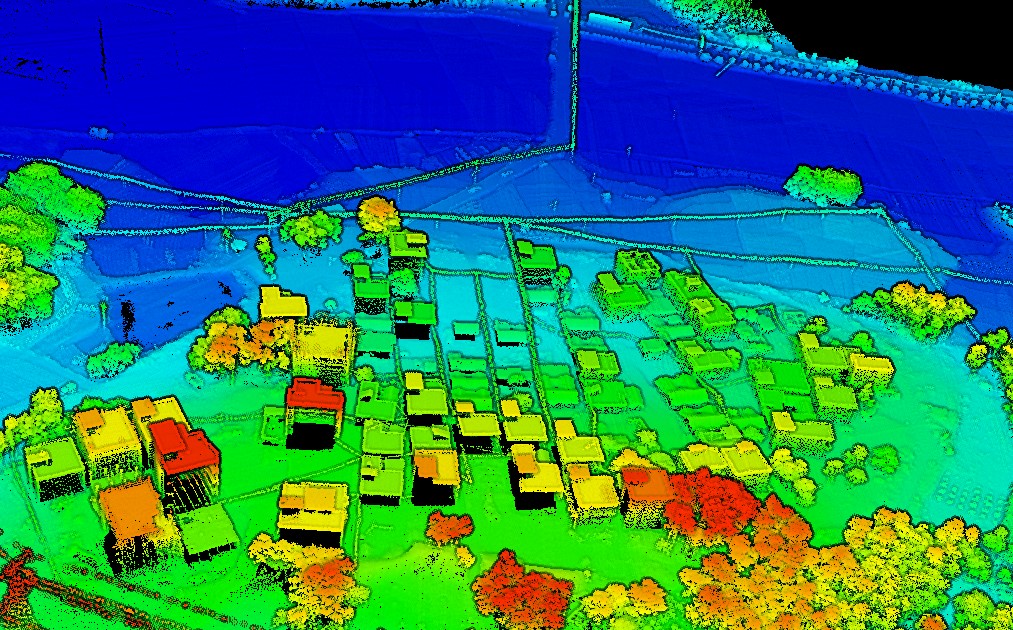

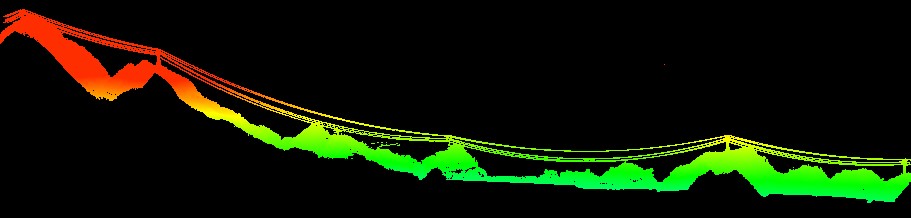

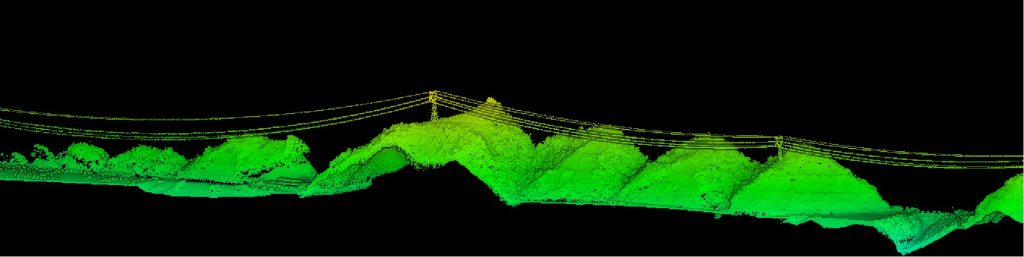

The mission involved the collection of LiDAR data for 52 km of power lines at 110kV and 220kV. Equipped with the JoLiDAR-LR22S, the CW-25E LiDAR drone could simultaneously collect point cloud and RGB data that can be used to create a digital twin of the overhead lines. By laser scanning the lines, towers, and surroundings, the CW-25E generated geo-referenced point clouds with an accuracy of 3 to 6 cm, which were then used to measure wire sag, vegetation height, or detect illegal structures in power line corridors.

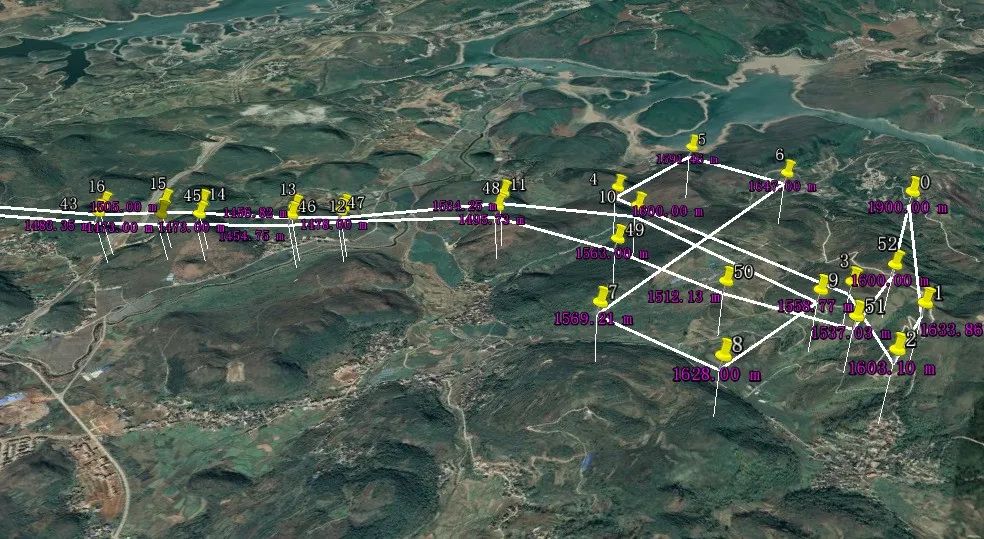

South China Power Grid staff set up ground base stations in places with no high-voltage lines and an open view

All the data collected was analyzed, defects detected, and reports generated. JOUAV's LiDAR post-processing platform software, JoLiDAR, was used to upload and process all collected data. Southern Power Grid analysts then classified, analyzed, refined, and resolved point clouds. The software quickly marked towers, extracted power line features, analyzed tree barriers, cable crossings, and more, while the platform's detailed reporting capabilities were used to outline the defects and locations found. The platform also provided task issuance and data management capabilities.

Step 1: Flight Plan

To tackle these challenges, Southern Power Grid sent a team of four drone pilots and one LiDAR expert. They used FlightSurv flight planning software to import the operation area kml file and modified the route according to the terrain height difference to achieve terrain-following flight.

Mission Planning:

- Flight height: 200m

- Flight strip spacing: 400m

- Flight mode: Terrain following

- Flight Speed: 60km/h

Visualization of an autonomous flight route in the flight planning software

Step 2: Data Collection

The LiDAR data were collected using a pre-programmed autonomous flight mode. The flight plan used accurate tower coordinates and digital elevation data to ensure that the UAV followed the correct flight path and maintained a constant altitude above ground level. The CW-25E LiDAR system scanned a total of 52 km of line, including the power plants at both ends of the road, and 142 towers in just 2 hours.

"It is good to see that the CW-25E UAV can work safely in the terrain with great height difference as well as at night. All equipment worked well and data collection was not affected in any way", Ken Wang commented, the drone pilot and LiDAR analyst at China Power Grid.

Step 3: Analysis and Results

The team uploaded the 33.7G of raw point cloud data collected during the inspection flight to JoLiDAR. It took 6 minutes to download the data and 50 minutes to generate the point cloud data. The average point cloud density was 38 points/m², and the highest point density reached 70 points/m². The data scanned during the LiDAR flight were georeferenced and analyzed by the team. The point clouds were then classified to separate different parts, such as towers, earth, and power lines.

"The CW-25E VTOL drone is 30 times faster than traditional foot patrols and 10-15 times faster than multi-rotor drones, “ Ken Wang said, the drone pilot and LiDAR analyst at China Power Grid. "In addition to data collection speed, the inspection process can be streamlined with the help of comprehensive LiDAR data processing software. JoLiDAR integrates data pre-processing, post-processing, and task management, which makes the analysis process faster, more efficient, and less error-prone".

In total, the team identified 74 critical defects during the LiDAR inspection. Distance measurements were performed based on parameters provided by Southern Grid. They categorized these defects based on their severity level:

A - Severity defect: 0 (less than 1 meter from the conductor)

B - Severity Defects: Class 4 (less than 3 meters from the conductor)

C - Severity defect: 105 (less than 5 meters from the conductor)

Vegetation: 30~100 point/m²

Tower: 70 point/m²

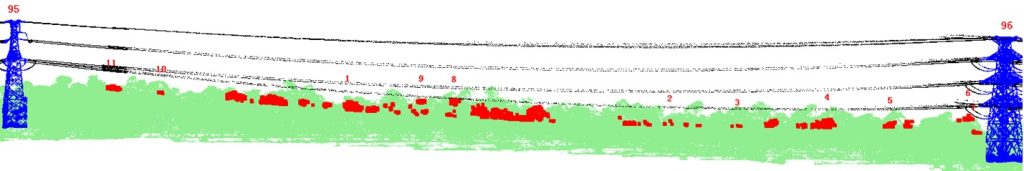

Barrier risk details

Barrier risk report

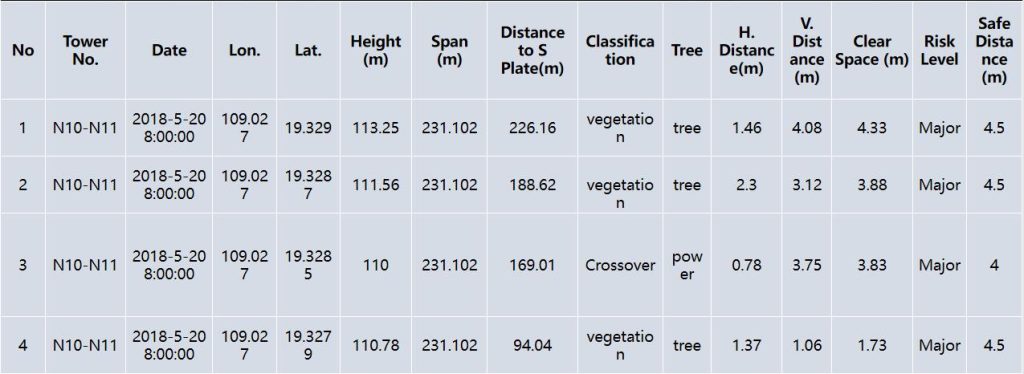

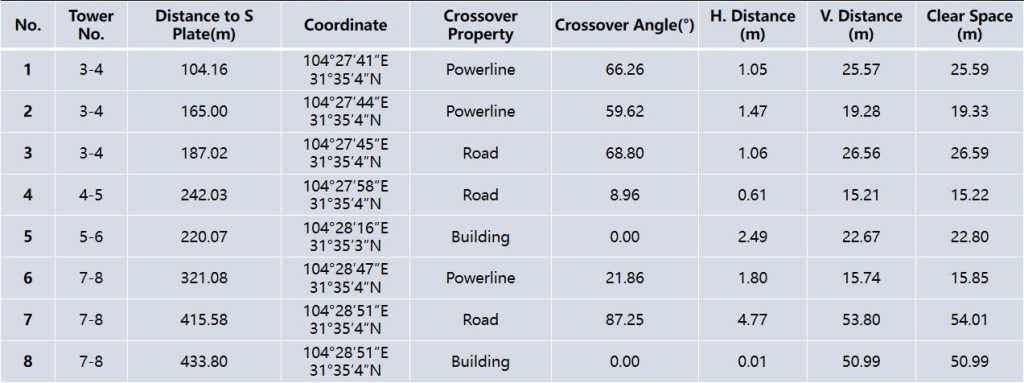

Crossover risk details

Crossover risk report

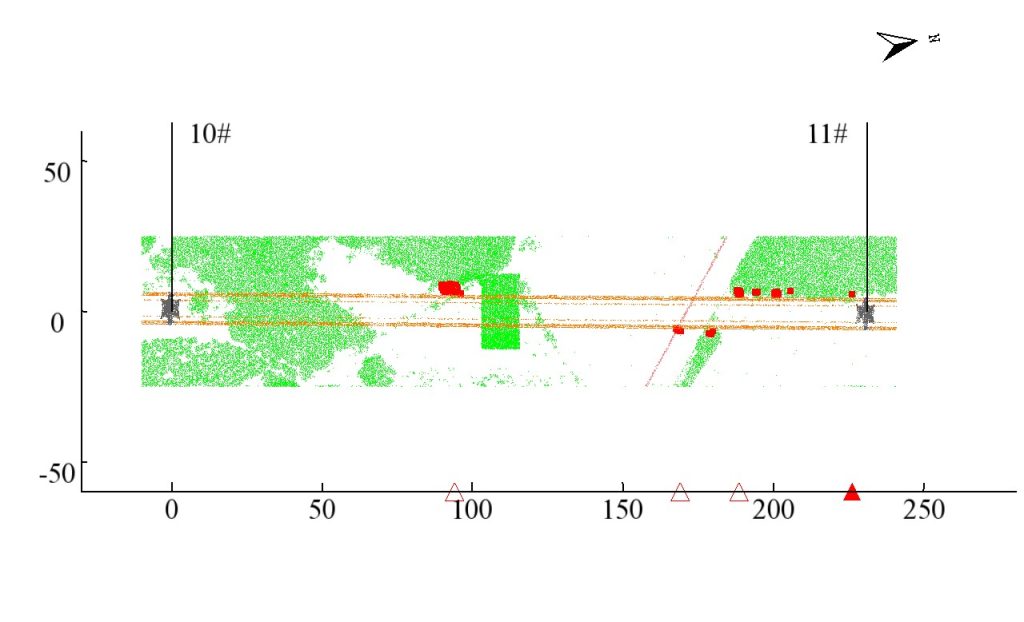

Sag measurement

Min. distance to the ground

Min. distance to the ground

220kV power lines

110kV power lines

Distribution powerline network

Power lines in high mountain areas

Power lines in high mountain areas

Conclusion

The use of JOUAV's CW-25E VTOL drone has enabled China Southern Power Grid to complete the inspection of 52km of power lines in just 2 hours, which is 30 times faster than traditional foot patrols and 10-15 times faster than multi-rotor drones. The drone-based inspection also provided higher accuracy and reliability than human inspections.

Despite facing several challenges, such as low temperatures, complex terrain, and a tight deadline, the team was able to overcome them by using advanced flight planning software and LiDAR technology. The data collected during the inspection provided valuable insights into the condition of the power lines, enabling the team to identify critical defects and prioritize maintenance and repair work.

Overall, the use of drone-based inspections has revolutionized the way China Southern Power Grid inspects power lines, improving efficiency, accuracy, and safety while reducing costs and downtime.