PT BUMA Improves Coal Mining Mapping Efficiency With JOUAV CW-007

In the rugged terrains of Indonesia's East Borneo, PT Bukit Makmur Mandiri Utama (PT BUMA) Jobsite IPR, a prominent coal mining service company, faced a daunting challenge - efficient and accurate mapping of their vast mining pits. Traditional methods fell short until they discovered the game-changing solution: JOUAV's cutting-edge CW-007 VTOL drone equipped with a CA-103 61MP RGB camera. Let's delve into PT BUMA's experience with JOUAV's remarkable product and the profound impact it had on their coal mining operations.

Company name | Bukit Makmur Mandiri Utama (PT BUMA) Jobsite IPR |

Country | Indonesia |

Application | Coal mine mapping |

Location | Tabang, East Borneo |

Drone model | CW-007 |

Camera sensor | CA 103 |

Software | CW Commander |

Coverage Area | 13.7km2 |

Time spent | 90 minutes |

Number of flights | 2 |

Average cruising speed | 20-21 m/s |

Flying altitude | 630m |

Ground resolution | 6.45 cm/pix |

Table 1. Survey data

Let's see how Agustinus W.R, Chief Surveyor of PT BUMA, operates CW-007:

Meet PT BUMA: Pioneering Mining Services

Established in 1998, PT Bukit Makmur Mandiri Utama (PT BUMA) has become a prominent player in the Indonesian mining industry, providing comprehensive coal mining services to major producers. With a workforce of approximately 11,500 employees and a fleet of over 3,500 heavy equipment units, PT BUMA has earned a distinguished reputation as one of Indonesia's largest mining contractors based on coal volume. Their longstanding relationships with industry giants like Berau Coal, Adaro Indonesia, Kideco Jaya Agung, Sungai Danau Jaya, and Pada Idi are a testament to their expertise and commitment to excellence.

Fig 1. All engineering team members from PT Bukit Makmur Mandiri Utama

Understanding the Challenge: Data Collection Efficiency

Facing an unyielding quest for continuous improvement, PT BUMA found themselves grappling with a recurring challenge - the demand for a more streamlined approach to field data collection. With the vastness of their operations, overseeing four expansive mining pits, they required accurate and timely data to optimize their coal production. Unfortunately, relying on conventional DJI multirotor drones for this task proved to be time-consuming, hindering their ability to promptly respond to operational changes and impacting overall productivity.

At PT BUMA, each passing week brought with it the urgent need to collect field data to monitor shifts in the pit and coal production. Yet, the process was strenuous and time-consuming, as Agustinus W.R, Chief Surveyor from PT BUMA said:

"We used to rely on DJI drones for data collection, but covering our extensive pits took forever. We knew we had to find a faster, more efficient solution."

Fig 2. PUMA members for the Tabang Coal mining mapping

Discovering the JOUAV CW-007 Solution

"We'd been on the hunt for almost a year, searching for the perfect drone. The CW-007 blew us away! Its efficiency in field data collection exceeded our expectations," shared Agustinus.

The JOUAV CW-007 VTOL drone and CA-103 camera formed an unbeatable duo that elevated PT BUMA's mapping endeavors. The CW-007, renowned for its rugged endurance of 70-90 minutes, enabled longer flight times, covering larger areas in a single mission. Cruising at a speed of 61.2 km/h and resisting winds of 10.8-13.8 m/s, the CW-007 navigated challenging terrains effortlessly.

The CA-103 aerial camera is the perfect companion to the CW-007, offering unparalleled image quality. With a massive 61.0-megapixel resolution and 35mm full-frame CMOS sensor, the CA-103 captures minute details, crucial for accurate mining data. Its continuous shooting capabilities enable PT BUMA to capture up to 10 photos per second in Hi+ mode, leaving no room for missed information.

Fig 3. PT BUMA members were doing pre-flight testing of CW-007

Superior Efficiency: CW-007 VTOL vs. DJI Multirotor

The mapping project in Tabang, East Borneo, covered an extensive area of 13.7 km². The JOUAV CW-007, with its impressive cruising speed of 20-21 m/s, completed the task in just 90 minutes, divided into two flights. With 615 images captured using the CA-103 camera, the drone effectively covered the entire area, providing essential data for the mining operations.

"Before we welcomed JOUAV into our operations, surveying a single pit used to be a time-consuming ordeal, taking up to 5 days. Now, with the CW-007, we can cover the entire area in just 90 minutes. The speed and efficiency are unparalleled, allowing us to focus on more critical aspects of our mining operations," expressed Agustinus.

Fig 4. The topographic maps produced with CA-103 data are rich in detail and high in accuracy, and they are produced faster, take up more space in the image, and have a lighter data load.

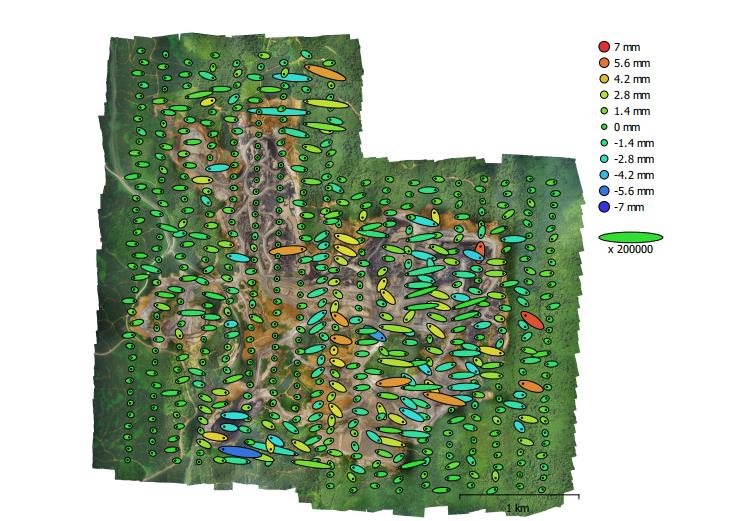

Pinpointing Precision for Enhanced Accuracy

Precision is the bedrock of any surveying project, and the JOUAV CW-007 and CA-103 camera combination exceeded expectations. The 608 camera stations, 660,893 tie points, and 2,142,840 projections demonstrated the comprehensive coverage and data quality achieved by the UAV system. With a minuscule reprojection error of 0.396 pix, PT BUMA could confidently rely on the precision of the captured data.

Fig 5. Camera locations and error estimates. Z error is represented by an ellipse color. X and Y errors are represented by ellipse shapes. Estimated camera locations are marked with a black dot.

X error (mm) | Y error (mm) | Z error (mm) | XY error (mm) | Total error (mm) |

0.413426 | 0.116823 | 1.52131 | 0.429615 | 1.58081 |

Table 2. Average camera location error. X - Easting, Y - Northing, Z - Altitude.

Georeferencing Perfection with Ground Control Points

Achieving accurate georeferencing is crucial for reliable mapping results. PT BUMA employed ten strategically placed Ground Control Points (GCPs) to calibrate and align the survey data. The RMSE analysis of these GCPs revealed impressively low errors, ensuring the mapping data's alignment with real-world coordinates.

Fig 6. GCP locations and error estimates. Z error is represented by an ellipse color. X, Y errors are represented by ellipse shape. Estimated GCP locations are marked with a dot or crossing.

Count | X error (mm) | Y error (mm) | Z error (mm) | XY error (mm) | Total (mm) |

10 | 5.42174 | 4.18046 | 2.00826 | 6.84628 | 7.13475 |

Table 3. Control points RMSE. X - Easting, Y - Northing, Z - Altitude.

Label | X error (mm) | Y error (mm) | Z error (mm) | Total (mm) | Image (pix) |

ta_1 | 5.33496 | 6.13132 | 0.594263 | 8.14911 | 0.536 (15) |

ta_2 | -0.255712 | -4.04668 | 0.46956 | 4.08185 | 0.295 (12) |

ta_3 | -2.35975 | 2.20335 | -0.332916 | 3.24561 | 1.174 (12) |

ta_5 | 7.46204 | -1.34308 | 0.721123 | 7.61616 | 1.823 (7) |

ta_6 | 4.77502 | -2.25871 | -1.11974 | 5.39967 | 1.397 (14) |

ta_18 | 5.53 | -0.416476 | -2.18745 | 5.96148 | 1.610 (12) |

ta_23 | -3.20125 | -9.23931 | -1.23464 | 9.85582 | 0.853 (13) |

ta_25 | 11.8426 | 4.32449 | -4.74308 | 13.4702 | 0.912 (14) |

ta_28 | -0.257603 | 0.972078 | 2.90103 | 3.07038 | 0.588 (12) |

ta_29 | -0.481938 | -1.96186 | 0.806525 | 2.17523 | 0.376 (8) |

Total | 5.42174 | 4.18046 | 2.00826 | 7.13475 | 1.045 |

Table 4. Control points. X - Easting, Y - Northing, Z - Altitude.

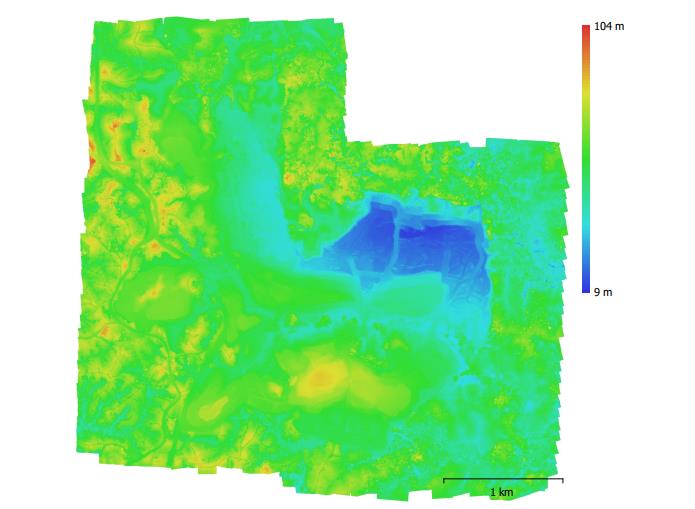

Empowering Decision-Making with Digital Elevation Models (DEM)

A thorough understanding of the mine's topography is crucial for optimizing mining strategies and enhancing safety. The Digital Elevation Model (DEM) generated by the CW-007 and CA-103 camera systems provides PT BUMA with highly detailed terrain data, including slopes, elevations, and hazards. With this valuable information, PT BUMA can make data-driven decisions to improve mining processes, reduce risk, and enhance operational efficiency and safety.

Fig 7. Reconstructed digital elevation model.

"Our mining operations rely heavily on the accuracy of data, and the JOUAV CW-007 and CA-103 camera surpassed our expectations. The detailed DEM generated from the data allowed us to identify potential hazards and make well-informed decisions, ensuring the safety of our workforce and the efficiency of our mining processes", said Agustinus.

Streamlining Operations with the JOUAV CW-007 Solution

The CW-007's smooth operation was made possible by the user-friendly CW Commander software. Its quick flight plan adjustments allowed PT BUMA's team to respond swiftly to dynamic conditions, ensuring uninterrupted data collection even in challenging scenarios. The drone's effortless assembly and operation were a breeze for the team, further supported by comprehensive training and unwavering support from JOUAV's experts.

"The CW-007's remote command capability using the CW Commander software was a total game-changer. It made our data collection a breeze," said Agustinus.

A 5-Star Experience with JOUAV

PT BUMA's transition to the CW-007 encountered a few challenges along the way. Telemetry signal interference within the mining environment and occasional camera malfunctions tested their resolve. However, with unwavering support from JOUAV's vendor team at Getindo and JOUAV's dedicated support team, these obstacles were promptly addressed and resolved.

Agustinus W.R. said: "We faced some initial challenges, but the support from JOUAV has been exceptional. They were responsive, understanding, and worked tirelessly to ensure we could maximize the CW-007's capabilities."

PT BUMA's satisfaction with JOUAV extends beyond its efficient products. The comprehensive training provided by JOUAV's team equipped their engineers with invaluable knowledge, ensuring a smooth drone operation. Furthermore, the prompt technical support from both JOUAV and its local distributor, Getindo, has helped resolve any challenges encountered during their drone operations.

"We give JOUAV 5 stars! The training was excellent, and the support they provided when we faced technical difficulties was exceptional. They truly understand our needs as a mining company and have been a reliable partner throughout our journey." - Agustinus W.R, Chief Surveyor from PT BUMA.

Conclusion

The partnership between PT BUMA and JOUAV, driven by the remarkable efficiency of the CW-007 VTOL drone, has set new standards in coal mine mapping. With its seamless integration, unrivaled mapping efficiency, and dedicated customer support, JOUAV has earned the trust and admiration of PT BUMA. The CW-007's swift and precise data collection capabilities have empowered PT BUMA to accelerate progress, optimize resources, and continue its journey as Indonesia's leading mining contractor. Together, they have redefined the future of mine mapping, leaving a lasting impact on the coal mining industry.