Offshore Oil Rig: A Comprehensive Guide

Deep beneath the ocean's surface, vast reserves of oil and gas lie hidden, waiting to be tapped. Extracting these valuable resources from the seabed is no easy feat, requiring innovation, cutting-edge technology, and an unwavering commitment to safety.

Offshore oil rigs, also commonly known as oil platforms, play a crucial role in this process, serving as massive industrial structures that stand tall amidst the waves.

From the very first offshore rig built in the 1940s to the behemoths operating today, these marvels of engineering have revolutionized the way we access these vital resources that power our world, from heating our homes to fueling our cars and countless other products we use every day.

In this comprehensive guide, we'll explore everything you need to know about offshore oil rigs, from what it is and how it works to how these giants are built and the crucial measures taken to ensure safety on these remote structures.

So, buckle up and get started!

What is an Offshore Oil Rig? What is the Difference Between it and an Oil Platform?

An offshore oil rig is a mobile platform primarily used for temporary operations, often in shallower waters, and for exploring or extracting smaller oil deposits.

A specific type, known as jack-up rigs, exemplifies this mobility as they can be transported by barges, lowered onto the seabed using long legs for stability during operations, and relocated once the task is completed.

In contrast, an oil platform is a massive and permanent structure firmly anchored to the ocean floor. These platforms are built for long-term operations in areas with abundant oil reserves, resembling large islands at sea.

They typically consist of three main components: a sturdy jacket acting as legs, a spacious deck for equipment and operations, and modules housing everything from drilling machinery to living quarters for the crew.

Examples include compliant towers with flexible supporting structures, SPAR platforms with a cylindrical design, and tension-leg platforms tethered to the seabed for additional stability.

How Does an Offshore Oil Rig Work?

The process of extracting oil from offshore reserves is complex and requires a comprehensive understanding of geology, engineering, and safety protocols. Let's delve into the intricate workings of offshore oil rigs, from initial exploration to production and transportation.

Check out the video below for how offshore oil rigs work:

Exploration Phase

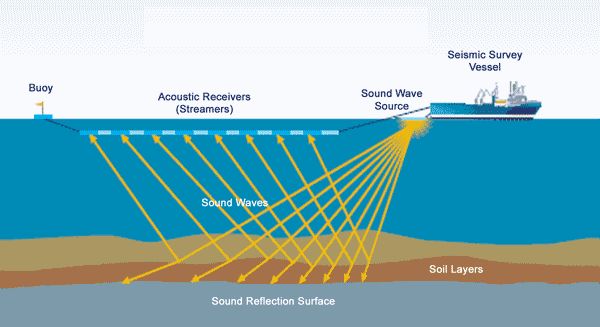

The journey of offshore oil extraction begins with exploration, where companies aim to identify potential oil reserves beneath the ocean floor. The first step involves employing sophisticated technology to survey the seabed. Utilizing sound waves emitted from devices equipped with compressed air, these waves penetrate the water, bounce off the seabed, and are captured by hydrophones. Through analyzing the data collected, scientists can pinpoint areas with promising oil and gas deposits.

Image source from noia.org

However, before drilling can commence, companies must secure leasing rights from relevant authorities. In the United States, jurisdiction over offshore lands is governed by acts such as the Submerged Lands Act (SLA) and the Outer Continental Shelf Lands Act (OCSLA). Furthermore, companies need permits from regulatory bodies like the Bureau of Safety and Environmental Enforcement (BSEE) to ensure compliance with environmental and safety standards.

Exploratory Wells

With leasing rights secured and permits obtained, oil and gas companies proceed to the next phase: drilling exploratory wells to confirm the presence of oil and assess its commercial viability. This critical step is executed using specialized drilling equipment known as Mobile Offshore Drilling Units (MODUs), which are designed to operate in various water depths and drilling conditions.

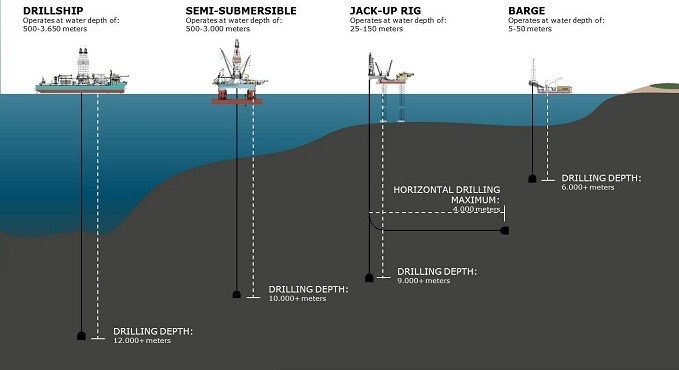

- Drilling Barges: Massive floating platforms used in calm, shallow waters. Anchored securely for drilling at depths of 15 to 150 feet, reaching depths beyond 3.7 miles.

- Submersible Rigs: Similar to barges, they can submerge part of their structure for stability, drilling up to 175 feet deep.

- Jack-Up Rigs: Versatile platforms with legs that can be lowered to the seabed, operating in depths of 80 to 500 feet, drilling beyond 5.6 miles.

- Semi-Submersible Rigs: Partially submerged for deep-water drilling, moored with advanced computer systems. Operating in depths of 1,600 to 9,800 feet, drilling over 6.2 miles.

- Drill Ships: Self-propelled vessels equipped for deep-water drilling, capable of navigating independently. Operating in depths exceeding 11,975 feet, drilling depths surpassing 7.45 miles.

Image source from noia.org

These MODUs are equipped with specialized drilling equipment, including a riser, drill string, blowout preventer (BOP), and casing strings. The riser extends from the rig's deck through the water column to the seafloor, providing a conduit for drilling operations. Metal casings are inserted into the wellbore to stabilize the formation, lined with cement for structural integrity, and sealed with elements like O-rings to maintain integrity.

If hydrocarbons are encountered during drilling, the well undergoes testing to assess reservoir properties such as pressure, flow rate, and fluid composition. Following successful testing, the well may be temporarily suspended or permanently plugged and abandoned if deemed unviable for commercial production.

Production Phase

Commercially viable oil wells transition to the production phase, where hydrocarbons are extracted, processed, and transported to shore. The choice of production platform depends on factors such as water depth, well depth, reservoir characteristics, and environmental considerations.

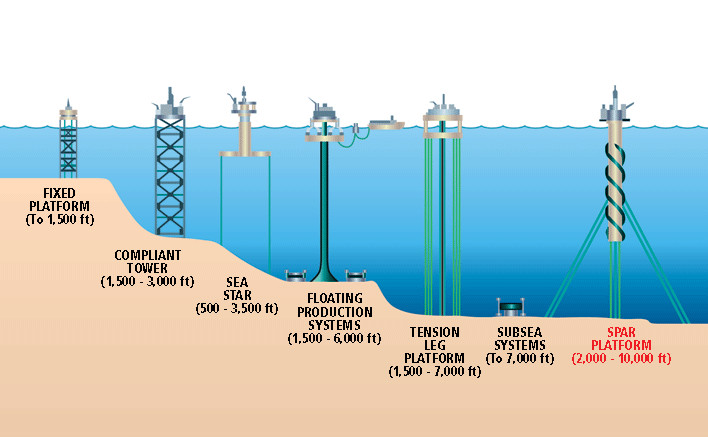

- Fixed Platforms: Traditional structures anchored to the seabed, ideal for shallow to moderate depths up to 1,500 feet.

- Compliant Towers: Tall, resilient structures engineered to withstand harsh conditions like hurricanes and rogue waves, suitable for depths of 1,500 to 3,000 feet.

- Tension Leg Platforms (TLPs): Platforms tethered to the seabed with vertical movement capability, designed for depths of up to 7,000 feet.

- Mini-Tension Leg Platform (Mini-TLP) or Sea Star (SStar): Smaller versions of TLPs for deep water and compact reservoirs.

- Floating Production Systems: Floating production, storage, and offloading (FPSO) vessels and units (FPUs) for ultra-deepwater environments where fixed platforms are not feasible.

- Subsea Systems: Deployed on the seabed for extracting hydrocarbons and transporting them via pipelines in extremely deep waters.

- SPAR Platforms: Cylindrical structures anchored to the seabed with tethers and anchors, deployed in depths up to 10,000 feet.

Image source from forbes.com

Production platforms are equipped with facilities for drilling, processing, and storage of hydrocarbons. They house essential equipment such as drilling rigs, production risers, wellheads, separators, pumps, and storage tanks. Additionally, these platforms accommodate personnel who work on a rotational basis, living and working onboard for weeks or months at a time.

Transportation

Offshore oil production relies on extensive pipeline networks to transport extracted hydrocarbons to onshore facilities for processing and distribution. Infield pipelines, also known as flowlines or feeder lines, connect subsea wells to production platforms. Export pipelines transport processed oil or gas from the platform to shore.

Additionally, shuttle tankers may be employed to transport crude oil from FPSOs to onshore refineries. These specialized vessels transfer oil via loading terminals, ensuring a continuous flow of hydrocarbons to market.

How Are Oil Rigs Built?

Building an offshore oil rig is a monumental task that involves meticulous planning, cutting-edge technology, and skilled workers. Let's explore the comprehensive process of constructing:

Check out the video below for how offshore oil rigs are built:

1. Design Phase

The journey begins with meticulous planning and design. Years of effort are poured into creating a blueprint for the rig, taking into account the harsh realities of its environment:

- Engineering Challenges: Every aspect, from the rig's size and shape to the materials used, undergoes careful consideration. The design must ensure the platform can withstand extreme weather, monstrous waves, and powerful currents.

- Environmental Considerations: Engineers meticulously analyze the intended location, factoring in water depth, currents, and wave heights. The platform needs to be designed to flex with the waves and survive the roughest seas.

- Target Resources: The type of oil and gas reserves the rig will target plays a crucial role. This dictates the selection of drilling equipment and influences the overall design.

- 3D Modeling: Once the initial design is complete, engineers create detailed 3D models using sophisticated computer-aided design (CAD) software. These models allow for virtual testing of various scenarios and fine-tuning of the design as needed.

2. Fabrication Stage

With a finalized design in hand, the construction phase kicks off. This stage involves building the various components that will eventually form the complete rig:

- Specialized Locations: Different fabrication facilities, equipped with cutting-edge technologies and materials, construction of the drilling platform, subsea systems (equipment for underwater operations), and living quarters for the crew.

- Logistical Marvel: Once built, these components are transported to the designated location for assembly. This necessitates a specialized fleet of ships and barges capable of maneuvering these massive elements through challenging waters.

3. Installation Phase

The various components, meticulously transported from fabrication sites, are carefully positioned and meticulously connected using cranes, welding equipment, and other specialized tools. This intricate process can take several months to complete and is crucial for ensuring the rig's safety and functionality.

4. Commissioning Phrase

Before the rig can begin its drilling operations, a series of rigorous tests are conducted:

- Pressure Tests: These tests ensure the rig's components can withstand the immense pressures encountered at such depths.

- Flow Tests: These tests verify the proper functioning of the systems responsible for transporting oil and gas.

- Electrical Tests: These tests confirm the integrity and reliability of the rig's electrical systems.

Owning a standard onshore drilling rig with a moderate capacity can range from $14 million to $25 million. However, offshore rigs are a different story altogether. Their construction costs can start at a staggering $20 million and skyrocket to a mind-blowing $1 billion, with drillships often topping the charts.

What Are the Hazards of Oil Rigs?

Despite the economic benefits, offshore oil rigs pose significant safety hazards. Workers face constant risks from moving equipment, falling objects, and high-pressure lines. Stringent safety protocols and proper equipment maintenance are crucial for mitigating these risks.

Struck-by/Caught-in/Caught-between

A staggering 60% of oil rig fatalities stem from these hazards. Moving vehicles and equipment, falling objects, and high-pressure lines pose a constant threat. Imagine a wrench slipping from a coworker's grasp and plummeting towards you, or a vehicle losing control and careening into a group of workers. Stringent safety protocols and proper equipment maintenance are crucial to mitigating these risks.

Fall Hazards

Oil rig workers navigate a complex web of platforms and equipment, often situated at dizzying heights. A misstep or a misplaced foot could result in a catastrophic fall. Fall protection measures, such as harnesses and secure railings, are essential lifelines in this environment.

Explosions and Fires

Flammable vapors and gases are ever-present on oil rigs, creating a constant threat of explosions and fires. Ignition sources like static electricity, faulty electrical equipment, or even a carelessly discarded cigarette can trigger an inferno. Oil rigs incorporate fire suppression systems, but preventing ignition in the first place is paramount.

Confined Spaces

Oil rigs house numerous confined spaces, such as storage tanks and wellhead compartments. These areas can harbor flammable gases and pose a risk of asphyxiation due to oxygen depletion. Workers entering confined spaces must adhere to strict safety protocols involving proper ventilation, gas monitoring, and buddy systems.

Ergonomic Hazards

The repetitive nature of many oil rig tasks, coupled with heavy lifting and awkward postures, can lead to a multitude of ergonomic hazards. These include muscle strain, back pain, and repetitive stress injuries. Implementing proper lifting techniques, utilizing ergonomic equipment, and incorporating regular breaks can significantly reduce these risks.

High-Pressure Lines and Equipment

Compressed gases and high-pressure lines are the backbone of oil rig operations, but they also pose a significant threat. Leaks or bursts can expose workers to high-pressure blasts, while faulty connections can transform these lines into dangerous projectiles. Regular maintenance and inspections are essential to ensure the integrity of these systems.

Electrical and Other Hazardous Energy

Unchecked electrical, mechanical, and hydraulic energy sources pose a grave danger on oil rigs. Faulty equipment or improper maintenance can lead to electrical shocks, mechanical entanglement, or uncontrolled release of energy. Implementing proper safeguards and adhering to strict operational procedures are crucial for mitigating these risks.

Machine Hazards

Rotating wellhead equipment like drawworks, pumps, and conveyors can inflict serious injuries if not handled with utmost caution. Workers must be adequately trained on proper operating procedures and maintain a safe distance from unguarded machinery.

Vehicle Collisions and Flight Accidents

Oil and gas workers often travel long distances to reach remote well sites, making them vulnerable to highway vehicle crashes. For offshore rigs, helicopter transportation adds another layer of risk. Defensive driving practices, proper vehicle maintenance, and rigorous pilot training are essential for mitigating these risks.

How Are Oil Rigs Maintained?

Maintaining an oil rig is not just a routine task; it's a meticulous process critical for ensuring safe and efficient operations in the demanding offshore environment.

Routine Inspections

Regular inspections serve as the foundation of preventive maintenance, allowing for early identification and mitigation of potential issues. A comprehensive inspection regimen includes:

- Visual examinations of critical equipment such as pumps, motors, valves, and pipelines to detect signs of wear, corrosion, or leaks.

- Structural assessments to identify any deterioration, including corrosion, fatigue cracks, or structural weaknesses.

- Electrical inspections to ensure the integrity of generators, switchgear, and lighting systems, minimizing the risk of electrical failures.

- Instrumentation checks to verify the accuracy and reliability of sensors, gauges, and monitoring devices crucial for operational control.

- Safety inspections to assess compliance with regulatory standards and industry best practices, ensuring a safe working environment for personnel.

Preventive Maintenance

Scheduled maintenance activities are essential for preempting equipment failures and sustaining optimal performance. Key preventive measures include:

- Regular lubrication of moving parts to minimize friction and wear, extending the lifespan of critical components.

- Routine cleaning and corrosion prevention measures to mitigate the risk of equipment degradation and contamination.

- Proactive replacement of worn or damaged components such as seals, gaskets, and filters to prevent unexpected failures.

- Calibration of instrumentation and control systems to maintain accuracy and reliability, enhancing operational efficiency.

- Systematic testing of safety mechanisms, including fire detection, gas detection, and emergency shutdown systems, to ensure readiness and effectiveness.

Corrective Maintenance

Swift and effective action is crucial when issues arise, necessitating efficient corrective measures:

- Detailed troubleshooting to identify the root cause of equipment malfunctions or failures, minimizing downtime, and optimizing repair strategies.

- Prompt repair or replacement of faulty components to restore functionality and prevent further damage or operational disruptions.

- Rigorous testing and validation of repairs to ensure safe and reliable operation, with thorough documentation of all maintenance activities for future reference.

Spare Parts Management

Efficient management of spare parts is paramount for minimizing downtime and optimizing maintenance workflows:

- Strategic identification and cataloging of critical spare parts based on equipment criticality, failure likelihood, and lead times for procurement.

- Establishment of robust supply chain partnerships with trusted suppliers and vendors to facilitate prompt procurement and delivery of spare parts.

- Secure and accessible storage of spare parts in designated areas on the rig, with appropriate inventory management systems to track usage, replenishment needs, and obsolescence.

- Continuous optimization of spare parts inventory through regular reviews and updates based on equipment performance and maintenance trends.

Safety Protocols

Upholding stringent safety protocols is non-negotiable in oil rig maintenance operations to safeguard personnel, assets, and the environment:

- Adherence to comprehensive safety procedures established by regulatory agencies and industry standards, with regular audits and reviews to ensure compliance.

- Ongoing safety training and drills for all personnel to enhance preparedness and response capabilities in emergencies.

- Mandatory utilization of personal protective equipment (PPE), including hard hats, safety glasses, gloves, and safety harnesses, to mitigate risks during maintenance activities.

- Strict implementation of lockout/tagout procedures to safely isolate and de-energize equipment before performing maintenance work, preventing accidents and injuries.

- Continuous risk assessments and hazard analyses to identify and mitigate potential safety hazards, with proactive measures to enhance operational safety and mitigate risks.

How Drones Can Make Offshore Oil Rig Inspection Safer and Faster?

Drone inspection offers fast, safe access to critical areas of oil and gas construction, mitigating health, safety, and environmental risks. It's a cost-effective alternative to traditional methods like rope access or scaffolding, providing quick visual assessments even in inaccessible locations, both onshore and offshore.

Benefits of Using Drones

Enhanced Safety: Drones have replaced risky practices like rope access or scaffolding, eliminating the need for human inspectors in hazardous areas such as flare stacks or high exterior sections. This significantly reduces the risk of accidents and injuries. A 2021 study by the American Petroleum Institute found a 75% decrease in potential fall incidents during offshore rig inspections when drones were used instead of manned crews.

Faster Inspections: Drones outpace traditional methods, thoroughly inspecting entire rigs in a fraction of the time. Compared to rope access or scaffolding, drone inspections can be completed 5-10 times faster, enabling quicker detection of issues and faster corrective actions. This translates to enhanced efficiency and shorter turnaround times.

Reduced Downtime: According to a study by the Uptime Institute, data center outages can cost businesses an average of $100,000 per hour. Unlike traditional methods that often require operations to be shut down, drone inspections can be seamlessly conducted while the rig remains fully functional. This minimizes production losses and associated costs.

Diverse Applications

Security

High-resolution cameras and thermal imaging capabilities enable drones to act as aerial guardians, detecting suspicious activity around the rig and deterring potential threats. Regular patrols offer broader coverage compared to traditional methods.

During a recent mission, JOUAV's CW-25D VTOL drone, equipped with an MG-150E gimbal camera, patrolled a vast sea area spanning 30-50 kilometers in diameter for a total of 4 hours across 4 flights. This successful operation greatly aided the Guangdong Provincial Public Security Department in apprehending smugglers and confiscating nearly a ton of contraband. For further details, please refer to the full case report.

Monitoring of Gas Emissions

Equipped with multi-gas detectors and sensors, drones become swift leak detectors for hazardous emissions. This ensures compliance with environmental regulations and allows for prompt action to address any issues.

Oil Spill Detection and Response

Early detection and measurement of oil spills are crucial for minimizing their spread and expediting response efforts. Drones provide real-time monitoring of the spill's size and movement, allowing for informed decision-making.

Offshore Rig Stability Monitoring

Ensuring offshore rig stability hinges on both the seabed composition and structural integrity. Traditional inspections (seabed hydrographic surveys & manual rig checks) are slow, risky, and costly. Drone technology offers a faster, safer, and more efficient solution.

Beyond seabed mapping with bathymetric cameras, drones equipped with high-definition cameras enable rapid rig inspections. Early detection of damage like cracks or corrosion allows for proactive maintenance, facilitated by advanced software that analyzes drone footage and automatically identifies issues.

Offshore Oil Platform Inspections

Drones aren't limited to seabed analysis. They can also be equipped with high-definition cameras for rapid inspections of the rig's structure. Early detection of potential damage, like cracks or corrosion, is vital for proactive maintenance. Furthermore, advanced software can analyze the drone footage, automatically identifying issues and allowing for preventive measures before problems become serious.

A real-world example demonstrates how a drone inspection completed a platform survey in just 10 hours, compared to the 30 hours required for manual methods. A customer recently used a quadcopter to gather visual data for inspecting structural damage on an offshore oil platform. This drone mission achieved the task in a third of the time compared to a manual inspection.

Flare Stack Inspections

Traditionally requiring a shutdown and posing a risk to personnel, flare stack inspections can now be conducted with drones while the stack remains operational. Real-time data streaming allows for immediate assessment and informed decision-making.

Integration of Artificial Intelligence for Corrosion Management

With the annual cost of offshore corrosion estimated at 60-80 billion USD, the integration of artificial intelligence offers a promising avenue for cost-effective asset management strategies.

AI models enable automated defect detection and trend analysis, thereby optimizing maintenance schedules and facilitating proactive intervention to mitigate corrosion-related risks.

Machine learning algorithms analyze inspection data collected by drones, facilitating the identification and segmentation of defects such as coating failures, corrosion, and structural damage, thereby enhancing the efficiency and accuracy of inspection processes.