Drones for Energy Industry: Top Use Cases and Best Models

Drone technology is quickly becoming a game-changer in the energy industry. With the global commercial drone market expected to reach $41.3 billion by 2026, energy companies alone are predicted to make up about $6 billion of that market.

This surge in adoption is no surprise—drones are proving to be invaluable for tasks like inspecting infrastructure, monitoring environmental conditions, and even planning for future expansions.

Whether it’s gas and water providers keeping an eye on their assets or renewable energy companies managing solar and wind farms, drones are helping to maximize efficiency and safety.

In this article, we’ll dive into the many ways drones are transforming the energy sector, exploring their use cases, success stories, and the significant benefits they bring to the table.

How Are Drones Used in the Energy Industry?

The drone applications span across various sectors within the industry, including oil and gas, renewable energy, and utility management.

Powerline and Transmission Tower Inspections

The power industry faces the daunting task of inspecting vast and often hazardous infrastructure. Traditional methods are time-consuming, costly, and pose significant risks to personnel. Drones have emerged as a transformative solution, offering unparalleled efficiency, safety, and accuracy in powerline and transmission tower inspections.

Equipped with thermal cameras, drones can identify overheating components, measure voltage levels, and detect potential electrical issues. LiDAR technology provides precise 3D models of powerlines, helping pinpoint structural problems, vegetation encroachment, and other hazards.

Real-time data processing, enabled by onboard software, allows for immediate analysis and decision-making. This streamlined approach improves response times and reduces the risk of power outages. Geo-tagged images pinpoint problem areas accurately, guiding maintenance crews directly to the issue.

Wind Turbine Inspections

Traditionally, inspecting wind turbines was a perilous and time-consuming task. Technicians had to physically climb these towering structures, risking their safety in often harsh weather conditions. This manual process was not only costly but also limited in scope.

Drones have transformed this industry. Equipped with high-resolution cameras and advanced sensors like LiDAR, these UAVs can effortlessly access hard-to-reach areas of wind turbines. They capture detailed images and precise measurements, revealing hidden damage, wear and tear, or erosion that human inspectors might miss.

Early detection is key to preventing costly breakdowns. By identifying potential issues upfront, wind farm operators can schedule maintenance proactively, maximizing turbine uptime and energy production. The data collected by drones also provides valuable insights into turbine performance, helping optimize maintenance schedules and make informed repair or replacement decisions.

Solar Farm Inspections

Drones have transformed solar farm maintenance. They offer unparalleled speed and precision, collecting data 50 times faster than traditional methods. This efficiency enables operators to optimize maintenance, pinpoint defects, and boost energy production.

Drones equipped with thermal cameras provide detailed, IEC-compliant data. This is crucial for warranty claims, as insurance companies often demand granular evidence. By detecting anomalies like hot spots, drones help identify faulty equipment.

Beyond warranty claims, drones are invaluable for long-term monitoring. By tracking solar farm performance over time, operators can identify trends, optimize maintenance, and make informed decisions.

Drones can also detect a wide range of defects, including faulty modules, cracks, defective inverters, string outages, defective trackers, shading, and reverse polarity. These issues can significantly impact solar farm efficiency.

Dams and Hydropower Plants Inspections

Drones have revolutionized dam and hydropower plant inspections, offering unmatched efficiency, safety, and precision. With aerial views and detailed data, they help engineers assess structural integrity, monitor water levels, and spot potential hazards.

Equipped with high-resolution cameras and sensors, drones can detect cracks, erosion, and other signs of deterioration in concrete structures. They also monitor vegetation growth near dams, identifying risks and informing management plans.

Drones capture images and videos of water levels and flows, aiding water resource management and flood control by estimating flow rates. They also inspect turbines, penstocks, and other equipment for damage, corrosion, or misalignment, ensuring proper operation of gates and valves.

Additionally, drones enhance security by monitoring dam perimeters, detecting unauthorized access, and identifying hazards like debris or wildlife that could impact operations.

Oil and Gas Infrastructure Inspections

Drones offer a safer and more efficient way to inspect vast oil and gas facilities. By automating inspections and providing a superior aerial view, drones can detect leaks that often escape traditional methods.

Drones equipped with thermal cameras can detect heat signatures associated with leaks, while high-resolution cameras can identify corrosion and other signs of deterioration. They can also monitor vegetation growth near pipelines, identifying potential hazards.

For tanks, drones can inspect the exterior for damage and corrosion, and estimate the level of liquid, providing accurate inventory data. They can also inspect pumps, valves, and other equipment for damage or malfunction.

Drones can monitor the perimeter of facilities, detecting unauthorized access or potential threats. They can also identify oil spills or other environmental hazards, monitor air quality, and detect gas leaks.

Site Surveys

Drones have become a game-changer for site planning in the energy industry. They offer a bird's-eye view that's invaluable for assessing terrain, identifying environmental impacts, and optimizing infrastructure layout.

Drones equipped with high-tech cameras can quickly create detailed 3D maps of potential project sites. This helps engineers pick the best spots for solar farms, wind turbines, or transmission lines. Plus, they can spot any environmental concerns, like rare plants or wildlife habitats, before it's too late.

During construction, drones keep an eye on progress, making sure everything's on track. Once a project is finished, drones can inspect it from top to bottom, ensuring it meets all the standards and is ready to go.

Emergency Response and Disaster Management

Drones can quickly survey affected areas, providing a comprehensive overview of damage to infrastructure. They can assess structural integrity, identify potential hazards, and guide repair efforts. Drones can also provide real-time information on the extent of damage, the location of affected areas, and the presence of hazards.

Drones can be used to search for missing persons and identify hazards that may pose risks to rescue personnel. They can also inspect power lines and transmission towers for damage, identifying areas where repairs are needed to restore power.

Drones can monitor the movement of supplies and equipment, ensuring efficient distribution to affected areas. They can also provide data on the extent of damage, helping to determine the necessary resources for recovery.

Best Drones for the Energy Industry

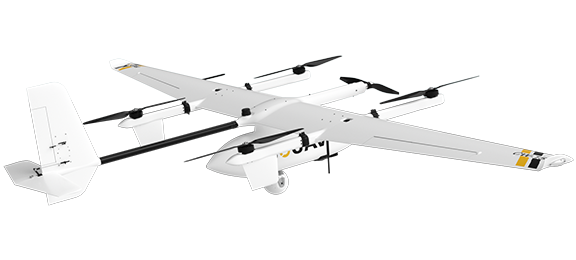

JOUAV is a leading name in drone technology, offering solutions that are perfect for the energy sector. Their drones combine advanced features with practical benefits, making them highly effective for various inspection and monitoring tasks. Here’s why JOUAV drones are a great choice for the energy industry:

Long Flight Time and Range: JOUAV drones are built for endurance, with flight times reaching up to 480 minutes and a range of up to 200 km. This means you can cover large areas or conduct long-duration inspections without needing constant recharges.

Versatile Payload Options: Whether you need RGB cameras, high-resolution oblique cameras, thermal sensors, or LiDAR systems, JOUAV drones can handle them. With payload capacities ranging from 1 to 20 kg, they’re adaptable to a wide range of inspection needs.

Customizable and Flexible: The open system architecture of JOUAV drones allows for seamless integration with various payloads and third-party systems. This flexibility lets you tailor the drone to your specific requirements, whether you need custom flight controls or specialized sensors.

Powerful Zoom Capabilities: For detailed inspections, especially on power lines, JOUAV drones come with gimbal cameras offering up to 30x or 50x optical zoom. This lets you capture clear, detailed images from a safe distance.

Safe and Smart Navigation: With millimeter-wave radar and four-directional obstacle avoidance, these drones automatically adjust their flight paths to avoid collisions, enhancing safety during complex inspections.

Autonomous Operations: JOUAV drones can be programmed to fly predetermined paths, making regular inspections easy to automate. This feature ensures consistent data collection and helps track changes over time.

AI and AR Integration: Advanced AI technology helps identify defects and hazards in real time. Augmented reality (AR) overlays on the live video feed highlight critical areas, making it easier to focus on important details.

Real-Time Data Processing: Thanks to LTE streaming to Jocloud, you can view and analyze data immediately. This cloud-based platform streamlines the inspection process, providing timely insights and improving decision-making.

JOUAV drones have a proven track record of delivering exceptional drone solutions to the energy industry, with numerous success stories demonstrating the value and impact of their technology.