Drone Inspection: Benefits, Process, and Applications

Visual inspection is a critical task for maintaining assets and ensuring safety. However, traditional methods, like manual inspections of tall wind turbines or pipelines, can be dangerous, slow, and inefficient.

Today, drones provide a much safer and more efficient alternative. Their ability to access remote, hazardous areas makes them ideal for inspecting infrastructure, power lines, and pipelines.

This article examines some basic ideas of inspection drones. It covers their advantages, applications, how to choose them, and the laws on their use.

What is Drone Inspection?

Drone inspection uses drones to check the condition of structures and infrastructure. Drones with high-resolution cameras, thermal sensors, and LiDAR capture detailed and accurate data in a much more efficient way than traditional inspection methods can manage.

The need for safer, cheaper, and better solutions drives the fast growth of the drone inspection market. MarketsandMarkets projects the drone inspection and surveillance market will grow from $11.6 billion in 2022 to $23 billion by 2027. That's a 14.6% annual growth rate.

Advantages of Drone Inspection

Drone inspections use cutting-edge tech. They eliminate many challenges of manual inspections. Below are the key benefits:

Enhanced Safety

The biggest advantage of drone inspection is the risk reduction to human workers. Inspections often require personnel to enter dangerous environments. These include tall structures, scaffolding, and confined spaces. These activities are dangerous. Workers face falls, accidents, and hazards.

It replaces the need for inspectors to go inside these high-risk areas. Drones can fly over or around the structure being inspected. This keeps personnel on the ground and reduces the risk of accidents and injuries. This heightened safety can help minimize insurance claims and keep the workforce healthy.

Reduced Need for Temporary Structures

Most traditional inspections required access to high, hard-to-reach spots using scaffolding, cranes, or lifts. Often, conducting such structures is quite expensive and time-consuming.

Drone inspections have access to these areas with no need to resort to expensive temporary infrastructure. This can save a lot, especially in tough inspections, like of high-rises, bridges, and power lines.

Lower Maintenance Costs

Normally, inspections are a starting point for undertaking maintenance. However, most inspections reveal no necessary maintenance to be done at all. Drones for inspections save companies from high scaffolding costs in cases that don't need repairs.

Building scaffolding only when needed can cut costs by 80–90%. This can translate into savings of tens of thousands of dollars, even hundreds of thousands of dollars.

Minimized Downtime

For industries that depend on continuous operation, like power plants, downtime is costly. Traditional inspection methods usually require shutdowns and scaffolding. This can take hours or even days.

Drones can ensure quicker and more efficient inspections of structures at much lesser downtimes. It saves money. But, more importantly, it will extend the life of turbines, reactors, and pipelines. They can boost overall revenue.

This will save money and may extend the lives of major assets, like turbines, reactors, and pipelines. Their continued operations will increase overall revenue.

Reduced Liability Insurance Costs

Drones cut the time workers spend in hazardous conditions. So, companies can reduce their liability insurance. By reducing inspections in dangerous conditions, a business can cut accidents and claims. This can lead to big savings in insurance.

Increased Inspection Frequency

Also, drone inspections are cheap and easy. So, companies can inspect facilities far more often than with traditional methods.

Regular inspections can catch issues early. This may prevent more serious problems and reduce long-term maintenance costs.

More inspections improve compliance with regulations. Companies can prove proactive asset management and safety.

Improved Data Accuracy and Record Keeping

With high-resolution cameras, thermal sensors, and LiDAR on each inspection, drones provide detailed, accurate data during each inspection. This information can be stored and accessed over time, building a comprehensive digital record of the condition of an asset.

This record will help us understand wear and tear. It will also help us predict maintenance and manage assets. The detailed visuals and data boost transparency for stakeholders. They also simplify audits and regulatory checks.

What is the Drone Inspection Process?

The drone inspection process involves a series of well-defined steps to gather accurate data and assess the condition of structures, equipment, or landscapes.

Preparing for the Drone Inspection Mission

1. Obtaining Permits and Permissions

Permissions required need to be consulted with local aviation authorities like the FAA in the United States. Many times, drones have to obtain special certifications or items that are waived from regular permissions, especially during tasks and flights near airports or restricted airspace outside of BVLOS.

There are different tools, such as the Low Altitude Authorization and Notification Capability (LAANC) app from the FAA, which will facilitate this process and make it faster and more accurate for you to gain these permissions.

2. Conducting a Site Survey

Assess the area to be inspected for hazards such as power lines, tall structures, and adverse weather conditions. Also, identify obstacles such as trees or buildings. A site survey will assist in determining the safest route of flight and where close inspection should be focused.

3. Planning the Flight Path

Create a detailed flight path based on your site survey. A good flight path maximizes coverage while minimizing flight time and risk. Consider local terrain, weather, and mission objectives in developing a safe and effective route.

4. Performing a Pre-Flight Check

Have a proper pre-flight check to ensure the readiness of the drone. Check on battery level, propeller integrity, camera calibration, and GPS accuracy. This prevents malfunctioning and requires high-quality data.

Capturing High-Quality Data and Images

During the inspection, focus on capturing clear, detailed visuals, which are essential for accurate analysis. This phase requires attention to flying techniques, camera settings, and environmental factors.

1. Optimizing Flight Parameters

Flying at the correct altitude and under suitable weather conditions ensures consistent data quality.

- Altitude Settings: Set the altitude according to what is needed for the inspection. For smaller structures, flying at a lower altitude can get closer detail, while at higher altitudes can fly over larger areas.

- Weather Conditions: Fly during the day when the weather is clear. Weather that is too windy, foggy, or rainy will affect image clarity and stability of data.

2. Camera Stability and Angle Adjustment

This smooth imagery is essential during detailed inspections that require precision.

- 3-Axis Gimbal: The camera of a 3-axis gimbal is stabilized on three planes, reducing any sort of blurriness. This is quite helpful in windy conditions or when making sharp turns to grab sharp visuals.

- Camera Angle and Perspective: It's important to take full advantage of camera-angle manipulation to optimize viewing perspective. Roof inspections may want a tilted camera angle, while cell towers may need to rotate 360 degrees.

3. Camera Settings for Quality Control

Adjusting camera settings can significantly impact image quality and detail.

- Exposure/White Balance: A histogram is used for adjusting the exposure so that the resulting image would present a balance of both highlight and shadow detail. The white balance shall be adjusted to match the color characteristics of the ambient light for realistic colors.

- Shutter Speed and Focus: Shutter speed increased will prevent blurring from the occurrence of motion, especially when the environment is windy. For capturing more critical details, try using manual focus or focus stacking.

- Grid Lines: Grid lines on the camera screen assist well in compositions, especially for shoots involving structures that must have perfect leveling.

Analyzing and Interpreting Drone Data

Once the data has been captured, it then requires processing and analysis to bring out any meaningful insights. This involves the use of specific software that will take raw drone footage and turn it into an action report.

Software Tools for Data Processing

There are a number of software tools that make this conversion of drone data into usable information easier. These are:

- Pix4D: This is a photogrammetry software used in mapping and creating 3D models.

- DroneDeploy: A cloud-based platform for the processing, analysis, and sharing of data.

- Agisoft Metashape: This is a powerful tool that allows the creation of 3D models and orthophotos out of drone imagery.

- ArcGIS Pro: Advanced GIS software, which provides comprehensive ways of conducting analysis and publishing geospatial data.

Analyzing Drone Inspection Data

The techniques that can be carried out to locate some problems or anomalies in the analysis phase are as follows:

1. Image Comparison: Changes like cracks, erosion, and other forms of structural weakness can be identified by comparing images from different flights or at different times.

2. Point Cloud Analysis: This is done through the creation of 3D models, in which one can identify anomalies in terrain or structure.

3. Clustering of Data: Similar data clustering helps in the identification of patterns and hotspots that indicate wear and tear or other damage.

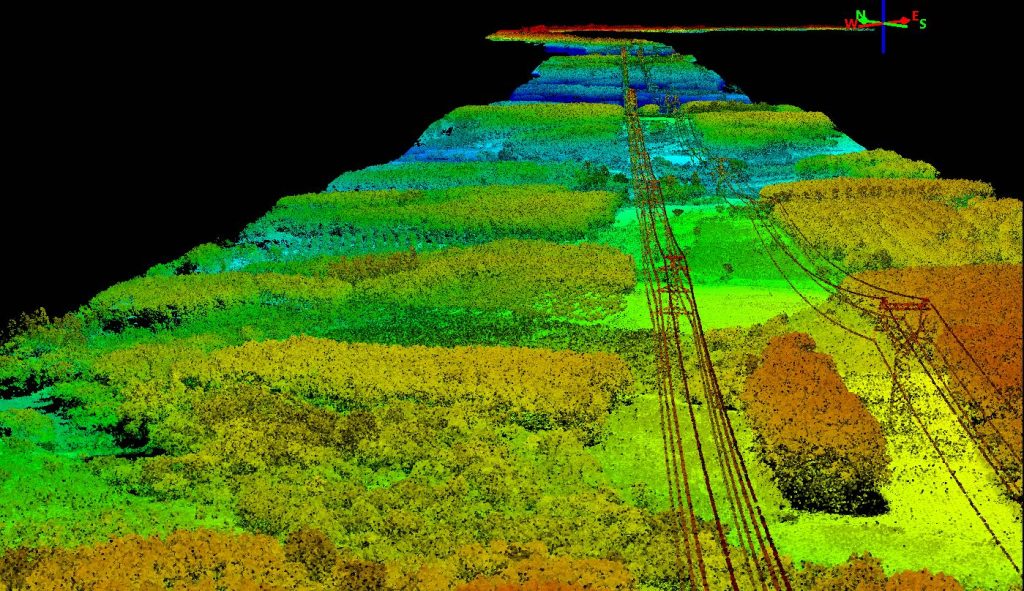

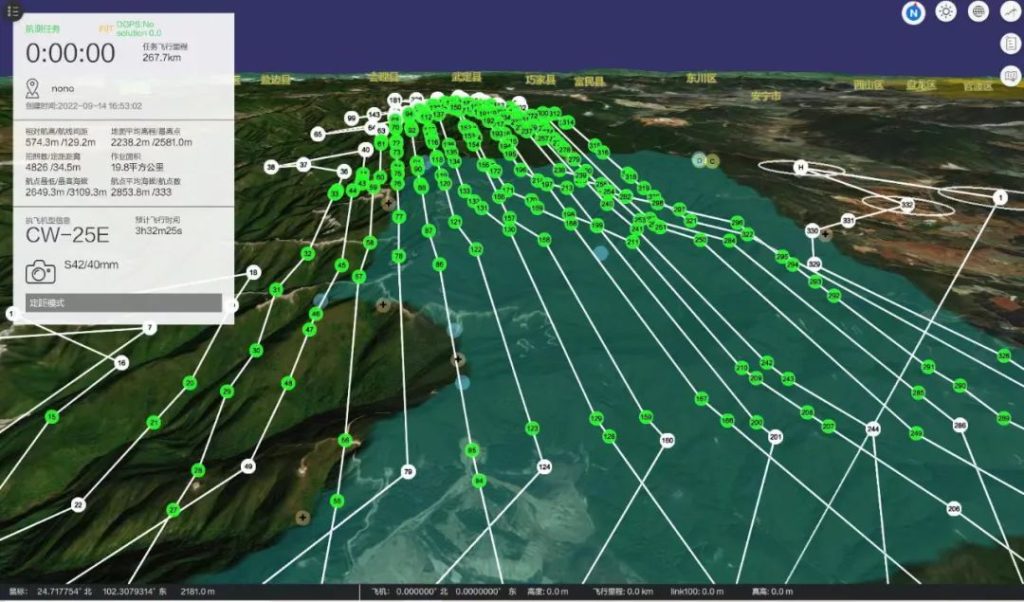

China Southern Power Grid used the CW-25E VTOL drone in high-altitude, icy regions, covering 52 kilometers of power lines in just two hours. The drone generated a high-density 3D point cloud, with vegetation density ranging from 30 to 100 points per square meter.

Report Generation and Visualizations

Creating inspection reports is essentially all about communicating findings to interested parties. Here is how you can make your reports more convincing:

- 2D/3D Mapping: Create detailed mappings and models to serve the purpose of better visualization of the site of inspection and bring out the areas that need attention.

- Heat Maps: Visualize, through differences in color, problem areas such as temperature anomalies or areas with high moisture.

- Actionable Reports: Clearly summarize findings with actionable recommendations. Include charts, graphs, and other visualizations that illustrate data in an easy-to-understand format.

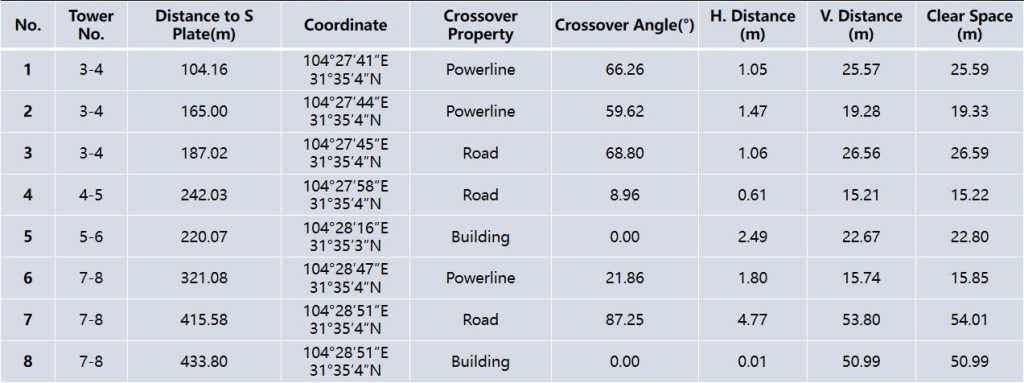

Using the LiDAR data collected by the CW-25E, a power line crossing risk report was created to identify potential hazards. Click to view the full case study for more details.

Decision-Making and Action

Once the analysis of drone data has been made and insights have been garnered, one course of action would be to make decisions based on those insights and act quickly. This phase involves interpreting findings, prioritizing risks, coordinating with stakeholders, and implementing corrective measures.

1. Interpreting and Prioritizing Findings

Not all the identified issues will fall under immediate action. It is at this stage that the decision-making process actually begins by categorizing findings into urgency and impact so that resources can be well allocated.

A typical RSA methodology includes:

- Risk Assessment: A list of findings ranked according to severity, likelihood of progression, and consequences. Structural issues with critical infrastructure, such as bridges, may be prioritized immediately; minor surface cracks may trend over time.

- Impact Evaluation: Assess the potential impact based on safety, operations, and cost. For example, pest infestations can lead to quick action in agriculture, while soil erosion might have a minimal amount of damage and thus could be scheduled for the next planting season.

- Trend Analysis: Identify spot trends based on historical data or past inspections. Issues showing progressive deterioration, like corrosion on power lines, must be ranked higher than those anomalies that have remained unchanged and were considered non-critical.

2. Stakeholder Involvement and Formulation of Action Plans

Most decisions would naturally involve several departments and stakeholders. Once issues are prioritized, findings would be presented to all concerned, and action plans developed in order to arrive at a consensus with effective solutions.

Key ones would include:

- Stakeholder Collaboration: Present findings in a format that is easily understandable by non-technical stakeholders through heat maps, risk severity charts, or the use of simplified 3D models.

- Cross Departmental Coordination: Engage departments such as maintenance, safety, and finance in considering all views on the subject. The maintenance teams can contribute to giving practical repair steps, while the finance teams can give some sense into budgeting.

- Regulatory Compliance: It aligns the action plans to industry standards and legal requirements, considering how strict regulations are within the utility and transportation industries.

3. Corrective Action Implementation

A decision has been made and now corrective measures shall be applied per the outcome of inspection. It may include immediate repair, scheduled maintenance, or even continuous monitoring of the situation.

- Immediate Repairs: For high-risk findings, immediate action is required to avoid possible accidents or loss of operational time. For example, in some energy inspections, emergency repairs are made on damaged insulators or cables to avoid blackout situations.

- Scheduled Maintenance: For medium-priority issues, defined by a condition not urgently needing repair but should be given attention to prevent escalation, routine or preventive maintenance is scheduled. For example, structural reinforcements on infrastructure are scheduled during periods of light traffic flow.

- Follow-up Inspections-Scheduling: Schedule follow-up inspections for minor or inconclusive issues to monitor changes. This ensures that small problems-like minor surface cracks-are dealt with before they can get worse.

4. Documenting Actions and Tracking Outcomes

Perhaps the most important part of any decision-making process involves documenting actions taken and evaluating their outcomes. In this manner, a feedback loop is instituted that strengthens future decision-making and allows for continuous improvement.

- Recordkeeping: Thereby, provide detailed records of every single activity, from findings and decisions to the repairs or interventions made. This will be useful and handy in all future inspections and audits.

- Evaluation of Outcome: Monitor the results of corrective actions taken so as to evaluate the effectiveness of those particular actions. For example, when replacing the damaged parts of a wind turbine, subsequently follow up on its performance and stability in order for the intervention to be effective.

- Continuous Improvement Feedback Loop: Integrate insights gained from each inspection cycle into future inspection criterion refinement, revised threshold levels of risk, and decision-making frameworks. This would be a step towards iteration for the betterment not only of the inspection process itself but the capability of response by the organization.

5. Application of Predictive Analytics and Automation to Future Decision-Making

Predictive analytics powered by AI, together with automation, further empowers decisions via actionable insights into emerging risks that have not yet fully taken hold.

- Predictive analysis: Such analysis would make use of machine learning models to predict possible failures or deterioration from available data at present and in the past. A typical example would be algorithms predicting the point at which a bridge will require maintenance based on wear and tear patterns identified in drone data.

- Automated Alerts: Establish automated alerts within software packages that will be triggered by new inspection data showing the development of high-risk issues and automatically notify teams. This will enable proactive decisions and early intervention.

What's the Best Drone for Inspections?

To choose the best drone for inspections, consider several key factors. They ensure quality and efficiency.

High-Resolution Camera

In most inspections, especially in roofing and infrastructure, camera quality is crucial. A drone should be fitted with a camera capable of shooting 4K or 5.2K resolution images.

A large sensor size helps the camera capture fine details. This is vital for spotting small issues, like cracks, leaks, or wear.

The camera settings must handle changing light. They should capture clear, accurate images in low-light and high-contrast situations, like shadows on buildings.

The PH-20 drone offers versatile capabilities, carrying up to three sensors and a dropper for varied data collection.

Thermal Imaging Capability

Thermal imaging is now a key tool for many inspections. These include roofing and utilities, as well as energy infrastructure. Drones, equipped with thermal cameras, can detect heat variations. This reveals hidden problems, such as insulation flaws, moisture buildup, and electrical faults.

They are also used in locating sources of heat loss, intrusion of moisture, and damaged insulation that is not visible to the naked eye. Thermal imaging is very useful for some inspections, like energy audits and leak detection.

The problem is that thermal-equipped drones are more expensive. So, they are only worth it for operations that need to use the feature often. Alternatively, clients must be willing to pay more for detailed analysis.

Flight Stability and Wind Resistance

Inspection drones must be able to operate in various environmental conditions. Most inspections require precise positioning near structures, like roofs or towers. So, the drone should fly stably.

Look for drones featuring GPS stabilization, robust motors, and wind resistance. They can hover steadily in winds up to 20-30 mph, common during outdoor inspections.

The drone's stable flight results in clear, steady images and video. These are vital for accurate analysis and reporting.

Automated Flight and Mission Planning

Drones must support automated flight for consistent, efficient inspections. This is possible through GPS flight planning. It lets the drone fly on pre-set paths. It ensures it flies the same pattern every time. This is vital for repeatable results. It's key when flying inspections overtime on the same site.

Automated flight saves time, improves safety, and cuts manual flying. The drone flies a preset course with minimal operator input. Also, many of these drones have mission planning software. It lets users set parameters like altitude, speed, and camera angles. This further optimizes the inspection process.

Obstacle Avoidance Technology

The main drone needed for this is one that can avoid obstacles on its own during close inspection of a target. In cluttered or confined spaces, targets require drone inspections of rooftops, chimneys, and power lines.

Obstacle avoidance systems use ultrasonic, optical flow, and infrared sensors. They detect and avoid obstacles in real-time. If it detects obstacles, the system will adjust the flight path. This will reduce the chance of a collision and damage to the drone or the asset being inspected.

Some have 360-degree obstacle sensors. They allow the drone to fly safely in all directions, even in tough, obstacle-filled environments.

Software Compatibility and Data Processing

Most professional inspection drones require specialized software for data acquisition, processing, and visualization. The best drones will have the most advanced software. It will allow flight planning, data gathering, image stitching, and 3D modeling.

Drones for aerial inspections can, for instance, connect to platforms that create orthomosaic maps, point clouds, or 3D models of the area. Such platforms allow for precise measurements and data analysis from the inspections.

They might be worth their weight in gold for decision-making and reporting. In this respect, compatibility with software like Pix4D, DroneDeploy, or Litchi is important.

Some inspection drones have proprietary software. It simplifies tasks by automatically processing data into easy-to-understand reports. This improves workflow efficiency.

Rugged Build for Professional Use

Among the main factors in commercial and industrial inspections is durability. Drones for inspection should be rugged and strong. They must withstand wear from frequent outdoor use in harsh weather.

Professional drones are weather-resistant. They resist water, dust, and other elements. This ensures the drone works in the rain or at high temperatures. Its functions won't be compromised. A strong drone reduces repair costs and downtime. So, it's a reliable way to do periodic inspections.

JOUAV PH-20's waterproof coating allows safe operation in moderate rain, ensuring reliable inspections in challenging conditions.

Ideal for complex inspections, the JOUAV PH-20 features a maximum flight time of 75 minutes, an operational range of 20 km, and a maximum payload capacity of 10 kg to carry up to three payloads and one drop kit together.

Equipped with advanced sensors, it has a 1080P 30x optical zoom gimbal camera and a 640x512 thermal camera for detailed inspection purposes, a 61MP camera for high-resolution image acquisition, and a LiDAR sensor for precise 3D mapping.

Types of Drone Inspections

Visual Inspection

With drones, visual inspections are possible from an elevated view to gauge the status of unreachable assets like power lines, chimneys, high-laying pipelines, and flares.

Drones fitted with high-resolution cameras take clear images and live video streams that expose surface issues like corrosion, cracks, and structural deformity.

Advanced drones today, like the JOUAV PH-20, feature strong zoom lenses, smart low-light capabilities, and extended transmission ranges that enable inspections beyond the visual line of sight.

Increasingly, automated drones boast collision avoidance and preprogrammed flight routes that hasten repetitive inspections, allowing consistent data capture and better management of assets.

Non-Destructive Testing

Certain sensors installed on drones perform NDT on industrial assets, making the process safer and more efficient since there is no need for direct human access.

Utilizing ultrasonic sensors, thermal cameras, and eddy current sensors, these drones detect a number of internal issues, such as structural flaws, heat anomalies, and material degradations.

For example, drones could be fitted with ultrasonic testing that measures wall thickness, detecting corrosion on storage tanks and chimneys. These drones fly toward the structure from any angle and measure all the minute details for predictive maintenance without disrupting operations.

Indoor Inspections

Indoor drones obtain particularly high value in the inspection of confined facility spaces, such as those in chemical plants, power stations, and mines where traditional access is very hard or hazardous.

Many of these drones, often caged for safety, navigate through narrow shafts, storage tanks, and pipelines using LiDAR mapping and obstacle avoidance.

Indoor drones may capture visual data, thermal imagery, and ultrasonic measurements that enable companies to assess structural integrity and environmental conditions without costly shutdowns.

Utility companies inspect big boilers using indoor drones, for example. It has reduced the time taken to complete the job by several folds.

Leak Detection

The detection of leakage by drones is highly essential in industries dealing in gases, chemicals, and other hazardous elements.

Drones equipped with sensors like thermal imagers and gas detectors are able to detect pipelines, storage tanks, and other infrastructure leaks with precise positions and detailed information on the severity and cause of a leak.

Advanced OGI sensors can detect methane, CO2, and many other types of gas by discriminating between natural emissions and those from leak sources at a distance of up to 100 meters.

Capabilities that improve environmental safety, avoid regulatory fines and enable speedy corrective action to protect both assets and ecosystems.

Drone Inspection Applications Across Industries

Infrastructure and Utility Inspections

Drones are used to inspect a wide range of structures, such as utility towers, bridges, railways, and roads. Drones have high-resolution cameras and sensors. They can quickly gather accurate data. So, they are ideal for routine maintenance and disaster assessments, like after hurricanes or floods.

The main advantage of drones in inspections is speed. Drones can inspect sites in hours, unlike traditional methods. Rappelling or heavy machinery can take days. Drones save time and money.

This is useful for structures in hard-to-reach or dangerous places, like high towers or bridge underbellies. Drones improve safety and efficiency. They eliminate the need for inspectors to access these areas.

Drones also make inspections more affordable. Traditional methods often require large teams, specialized equipment, and extensive planning. Drones allow one operator to collect the needed data. This cuts labor and equipment costs. This makes it easier to schedule frequent follow-up inspections, improving overall infrastructure monitoring.

In disaster scenarios, drones are invaluable for quickly assessing damage. They can fly over affected areas. They will capture real-time visual and thermal data. This will help evaluate infrastructure without risking human inspectors. This ability to gather quick, reliable data aids in decision-making and speeds up recovery efforts.

Structures commonly inspected:

- Bridges

- Air transport infrastructure (runways, airstrips, air towers)

- Railways

- Roads and highways

- Cell/telecom towers

- Water towers

- Dams

- Sewers

Powerline Inspections

Drones can inspect power lines and pylons in detail. They capture high-res images that reveal problems, like bird nests, lightning damage, rust, and loose bolts. The drones can find problems early and fix them. Their frequent inspections from various angles make this possible.

Drones check how close vegetation is to powerlines. They find trees or plants that might be a danger. These go into plans to manage vegetation. They prevent outages and reduce fire hazards from encroaching greenery.

With thermal sensors, they can also detect temperature changes along power lines. This can find hotspots, bad connections, or faulty insulation. These are anomalies that, if found early, prevent fires or equipment failures in utility companies. This is vital in areas that can support wildfires.

Drones can assess damage to power infrastructure from disasters, like fires and storms when access is too remote or dangerous. The quicker that happens, the quicker repairs and a full restoration of service and grid safety can be realized.

Structures commonly inspected:

- Transmission lines

- Power poles and pylons

- Insulators

- Transformers

- Substations

- Vegetation surrounding powerlines

Chemical Industry Inspections

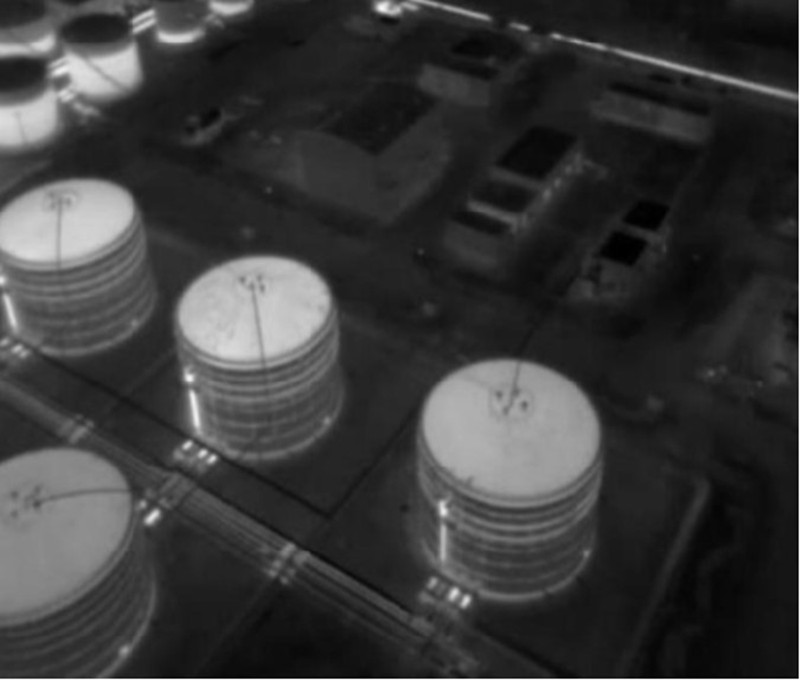

Drones are widely used in the chemical industry. They provide cost-effective and efficient inspections and monitoring. They have highly sensitive cameras and sensors. They are used to examine high-level assets, like flare stacks, distillation columns, and pipelines. They check for gas leaks, temperature anomalies, and structural issues.

Drones offer a safer alternative to human entry for inspections. They can inspect storage tanks, reactors, and pressure vessels in confined, hazardous areas. They can also check for leaks, cracks, and corrosion and find unwanted objects. Many have protective cages or collision-avoidance tech. It lets them fly through tight spaces.

These drones help analyze incidents faster in emergencies, like chemical spills or gas leaks. They provide real-time visuals to direct response teams. They can always be used to continually conduct site security monitoring to enhance safety and visibility.

Drones are best for surveying and mapping chemical plants and hard-to-reach areas, including underwater and underground pipelines. They can detect leaks and find operational problems. They can process the data into 3D models. This will streamline inspections and reduce the need for manpower.

Structures commonly inspected:

- Flare stacks and chimneys

- Distillation columns and reactors

- Storage tanks and pressure vessels

- Pipelines

- Cooling towers

- Heat exchangers and boilers

Building Inspections

The drones are very efficient in building inspection because they can easily, quickly, and safely reach inaccessible areas. Equipped with high-resolution cameras, drones capture highly detailed images of roofs, walls, and other exterior elements that let inspectors notice missing shingles, cracks, and water infiltration without scaffolding or physical access to such places.

These drones enable one to get a broad view of the surface conditions during roof inspections, hence the detection of any damaged shingles, flashing, and debris that could lead to leakage or further deterioration.

With respect to facade inspection, high-definition and thermal imaging by drones show all structural damages, cracks in walls, and insulation deficiencies; hence, thoroughly enabling assessment from various angles.

For structural deformations, such as leaning walls, the drones can make 3D models for more detailed analysis, hence guiding the inspectors in finding misalignment or other signs of instability.

Then again, drones identify risks emanating from vegetation encroachment and alert the inspectors where to trim to prevent structural damage or moisture retention. They also assess environmental hazards that would enable proactive maintenance and safety measures.

Structures commonly inspected:

- Roof

- Exterior and facades

- Foundations

- Chimneys and smokestacks

- Balconies and railings

- HVAC units and rooftop equipment

- Windows and doors

Construction Inspections

Construction drones enable fast mappings at the start of a project that turns updates pretty frequently, monitoring the progress and changes but also assessing in greater detail the condition of the site than traditional methods. Because this process is efficient, collaboration among the various teams becomes easier; this means timely access to data with fewer delays.

Equipped with 3D imaging capability, drones build detailed site models that compare actual progress against design plans. These models enable virtual walkthroughs that facilitate communication regarding updates on the project, reduce disputes among contractors, and flag potential hazards before they turn into expensive problems.

Drones are also of great value in inventory and asset management processes, enabling the tracking of equipment and materials in real-time. For example, on larger projects, drones can perform stockpile volume calculations to help quantify materials on hand, often in a matter of minutes, to ensure adequate resources for continuing tasks while minimizing safety risks for personnel.

Finally, drones enhance communication among stakeholders by providing easily accessible documentation that not only enhances the coordination of contractors but also helps ensure all facets of the project work together smoothly.

Structures commonly inspected:

- Foundations and site grading

- Structural frameworks

- Scaffolding and safety structures

- Retaining walls and slopes

- Stockpiles and material storage areas

- Road and pavement conditions

- Utility installations (e.g., pipes, cables, conduits)

Oil and Gas Inspections

Drones provide efficient surveillance across the oil and gas operation, from infrastructure through pipelines and rigs down to other remote assets. They are characterized by their 360o views and sensors for data acquisition of the extraction process, including condition monitoring of equipment and encroachment around critical sites, assuring consistent security and operational overview.

They come with close-view, high-accuracy inspections to locate leaks, corrosion, and structural damages before they get worse. With gas detection sensors mounted on these drones, they will be able to locate methane and other emissions, thereby enabling energy firms to meet stringent environmental standards. Other than that, drones do routine surveys to quantify emissions and assist with environmental compliance.

Drones observe damage, deliver supplies, and help first responders with live footage during emergencies. Some even have attachments designed to spray firefighting foam in case of fires, further making them important tools during quick incident responses.

Logistically, drones make it easier to move equipment into the most remote or hardest-to-reach areas using aerial access, hence making effective deliveries possible for otherwise inaccessible sites. This allows for the satisfaction of construction and emergency supply needs across generally hazardous landscapes.

Structures commonly inspected:

- Pipelines

- Oil Rigs (Onshore and Offshore)

- Storage Tanks

- Compressor Stations and Pumping Facilities

- Refineries and Processing Plants

- Marine Structures

Insurance Inspections

With the use of high-resolution cameras, drones capture property aerial imagery that enables insurance companies to determine damages without setting foot on the scene of a loss. This accelerates claim processing with more accurate repair estimates due to disasters such as storms.

Drones also provide pre-policy assessments to insurers in the evaluation of property risk before the issuance or renewal of policies. They can locate and identify certain hazards—such as the need for maintenance which could affect the insurability of the property and thus make informed decisions about premiums or coverage.

Moreover, drones combat fraud by providing impartial data for pre- and post-incident comparisons, hence guaranteeing nondiscriminatory settlements of the claim by confirming the pre- and post-event status of a property, therefore making it hard for customers to deceive insurers.

Structures commonly inspected:

- Roof

- Electrical

- Chimney

- Plumbing

- HVAC

Offshore Inspections

Offshore sites, such as oil rigs and wind turbines, are subjected to extreme weather conditions like high winds, rain, snow, hail, and saltwater, all of which cause wear and tear, leading to structural deterioration and corrosion.

Drones are equipped with non-destructive testing (NDT) tools that allow for detailed inspections of these sites without the need for costly and risky manual inspections. Using thermal imaging cameras, drones can detect temperature variations indicative of leaks, faulty equipment, or insulation issues.

Drones also help monitor the condition of pipelines, platforms, and other critical infrastructure, identifying potential issues such as cracks, leaks, or corrosion before they become serious problems. Additionally, drones can inspect the health of surrounding ecosystems, including water quality and air pollution levels, supporting environmental compliance and monitoring.

Structures commonly inspected:

- Oil rigs and platforms

- Wind turbines

- Offshore pipelines

- Floating production storage and offloading (FPSO) unit

- Subsea equipment

- Marine vessels and supply boats

Mining Inspections

Drones monitor mine stability, identify slope failure, and review general site health with a very valuable contribution. The creation of high-resolution imagery and 3D models means drones can provide critical data that enables safer and more efficient operations. They will monitor environmental factors such as water quality and vegetation, helping companies meet regulatory standards.

In underground mines, drones navigate through complicated, unstable environments to capture comprehensive visual and sensor data, therefore enabling companies to understand the condition of slopes, tunnels, and equipment without putting workers in jeopardy. By detecting hazards like rockfalls, water ingress, and equipment malfunction, drones save labor and efficiency.

Equipped with LiDAR and thermal cameras, mining drones amass a lot of data that can be analyzed by companies for insightful decisions. The data provide them with the power to improve safety while reducing costs and enhancing operations by determining remaining ore, equipment utilization optimization, and tracking environmental impact.

Structures commonly inspected:

- Pit walls

- Stopes

- Tunnels and shafts

- Tailings ponds and dams

- Berms and benches

Agriculture Inspections

Agriculture drones help farmers quickly inspect very large areas and offer the first signs of pests, diseases, and nutritional deficiencies through multispectral sensors that find crop stress much earlier than it can be seen. This early detection allows for timely action to reduce crop loss and enhance yield.

Advanced drones monitor key conditions of the soil, such as moisture, temperature, and pH important in helping the farmer understand variability in the soil and apply resources with precision. It is a targeted approach that will help a farmer minimize waste, cut costs, and support more sustainable practices.

Infrared sensors enable drones to position dry zones where irrigation should be implemented with high accuracy, conserving water but stimulating healthy plant development. Equipped with drone-sourced information, farmers can adjust the irrigation levels accordingly to improve crop quality and raise water efficiency.

By mapping nutrient and pest distributions, drones enable targeted fertilizer and pesticide application, reducing overuse and environmental impact. Some can even apply pesticides right to the affected area.

For livestock, drones equipped with thermal and optical sensors will monitor animal health and behavior through the detection of illness or injury to intervene. Drones will also monitor herd movement in order to improve welfare and reduce losses to disease or injury.

Structures commonly inspected:

- Crop fields

- Irrigation systems

- Soil health zones

- Livestock fencing and Shelters

- Drainage and Ditches

- Storage facilities and silos

Public Safety Inspections

In search and rescue, thermal imaging is used with drones to cover large areas rapidly and pinpoint missing persons in bad environments. They even can deliver supplies until the rescuers arrive, making the process much more efficient and quick.

Drones are providing real-time aerial intelligence in active events like wildfires or active shooter events. In firefighting, thermal sensors will find hotspots for locating and tracking fire spread," he said. "Inactive shooters, drones capture vital information from a safe distance that reduces risk to personnel.

Drones are also useful in crime scene investigations by taking high-resolution aerial shots to preserve the originality of the scene. This data helps the police reconstruct the events, gathering evidence without disturbing the site for an effective investigation.

Such drones improve congestion and movement tracking for crowd monitoring, hence establishing the buildup of any potential security threats like unattended objects. Besides, drones enable preventive inspections by mapping out public areas and giving aerial data for further security planning or investigations of crime scenes.

Legal and Regulatory Considerations for Drone Inspections

Drone inspections are subject to complex laws and regulations. They vary by country, region, and industry.

Licenses and Certification

In most countries, drone operators must have a license to operate commercially. These licenses ensure the pilot knows aviation rules and safety procedures.

In the U.S., commercial drone operators must be certified by the Federal Aviation Administration (FAA) under Part 107 of the Federal Aviation Regulations (FARs). This certification requires the pilot to pass a written exam. It covers topics like airspace classification, drone operation, weather, and emergency procedures. A medical certificate is not required, but operators must be at least 16 years old.

In the EU, the European Union Aviation Safety Agency (EASA) governs drone use. Operators are classified by the risk of their operations: Open, Specific, and Certified. Each category has different certification requirements. The "Open" category, for example, requires no specific certification for drones under 25kg. But, pilots must follow specific rules. The "Specific" category applies to higher-risk operations. They require authorization and a risk assessment.

Airspace Authorization

Drone operations must follow airspace regulations. They keep drones from interfering with manned aircraft.

In many regions, drones can't fly in controlled airspaces, like near airports or military zones. The FAA classifies U.S. airspace into several categories: Class A, B, C, D, and E. Class B airspace, near large airports, is especially restricted. Drones cannot fly in these areas without special authorization.

In the U.S., the FAA has a system called LAANC. It lets drone operators request and receive real-time airspace authorizations for controlled airspace. This system is useful for commercial drone inspections near airports or other controlled areas.

Many drones have geofencing tech. It prevents them from entering restricted airspaces. This is crucial in urban areas, where drones may enter no-fly zones.

Privacy and Data Protection

Drone operators worry about privacy laws. This is a concern when they inspect properties or infrastructure in populated areas.

The GDPR (General Data Protection Regulation) sets strict rules on personal data in the EU. It covers its collection, storage, and use. If drones collect identifiable information, the operator must comply with GDPR. This includes images of people and private property. This includes obtaining consent when needed and protecting personal data.

Drone operators should collect only the data needed for the inspection. They must avoid capturing irrelevant personal information. Data retention policies should also be in place to ensure compliance with data protection laws.

Some states may have privacy laws that govern drone use, in addition to national regulations like GDPR. In California, the CCPA protects consumer privacy. It may apply to drone data collection.

Operational Limitations

Drone operations for inspections are subject to strict operational restrictions to ensure safety.

In the U.S., the FAA limits drones to 400 feet. They may fly up to 400 feet above a structure if they are within 400 feet of it. Similar altitude limits exist in other countries, such as the UK and Australia.

Drones must usually be flown within the operator's visual line of sight (VLOS). The operator must always see the drone with the naked eye. This requirement can be relaxed under special conditions, like BVLOS operations. But operators must apply for waivers in such cases.

Many jurisdictions restrict nighttime drone flights. Operators need special equipment, like anti-collision lights. They also need waivers or certifications for night flying.

Drone operators must ensure they are aware of and comply with weather-related restrictions. Strong winds, heavy rain, and other adverse conditions can make drone flights hazardous. Most consumer drones resist winds of 20–30 mph. Commercial drones can withstand higher gusts.