Brushed vs. Brushless DC Motor: What’s the Difference?

When it comes to drones, the type of motor you choose can make a world of difference. Many motion control applications use permanent magnet DC motors because they simplify control systems compared to AC motors.

For drones, there are two main types of DC motors: brushed and brushless (BLDC). Brushed motors use physical brushes to commutate the motor, while brushless motors rely on electronic control for commutation.

Choosing the right motor is crucial for achieving the best flight time, efficiency, and maneuverability.

Whether you’re a hobbyist or a professional, understanding these differences will help you select the motor that best fits your drone’s needs.

This article explores the key distinctions between brushed and brushless motors, their benefits and drawbacks, and how to make the best choice for your drone.

What is a Brushed DC Motor and How Does it Work?

The brushed DC motor, a stalwart in the world of small motors, has powered countless applications for over a century. Its simple and robust design makes it a popular choice, even finding its place in the early days of drones.

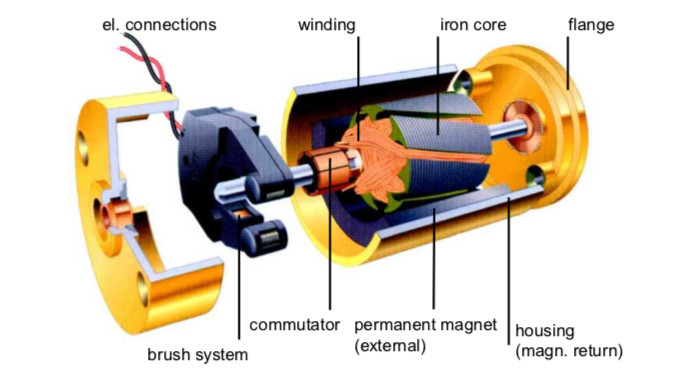

Key Components:

- Stator: The stationary part of the motor that provides a magnetic field, usually through permanent magnets. These magnets are positioned on the inner surface of the stator, outside the rotor.

- Rotor (Armature): The part that spins. The rotor consists of wound coils of wire that create a magnetic field when electricity flows through them. These coils are typically wound around an iron core, although some motors use "coreless" windings.

- Commutator: A rotary switch attached to the rotor. It reverses the direction of current flow through the rotor windings, ensuring continuous rotation.

- Brushes: Fixed conductive materials, usually made of carbon, that maintain electrical contact with the rotating commutator.

Source: maxongroup.com

How Does a Brushed DC Motor Work?

When DC voltage is applied across the brushes, current flows through the rotor windings, generating a magnetic field around the rotor. The interaction between this magnetic field and the stationary magnetic field of the stator creates forces that cause the rotor to turn.

As the rotor turns, the commutator rotates with it, switching the current direction in the rotor windings. This switching process, known as commutation, ensures that the magnetic field of the rotor continuously changes, maintaining rotational motion by alternating the attraction and repulsion between the rotor and stator magnets.

Source: renesas.com

Due to the physical contact between the brushes and commutator, mechanical friction occurs, leading to wear over time. This wear can eventually cause the motor to malfunction. Many brushed motors, especially larger ones, feature replaceable brushes made of carbon to extend their lifespan. However, the commutator itself will also wear out eventually, requiring motor replacement.

For simple applications, such as motorized toys, brushed motors can be driven by merely switching the DC voltage on and off. Electronic drive circuits like an H-bridge are used in more advanced applications requiring control of speed, torque, or direction. This setup allows for precise motor direction and speed control by varying the voltage polarity and using pulse width modulation.

Brushed DC motors are valued for their straightforward design and cost-effectiveness. They are commonly used in applications where simplicity is preferred and maintenance is manageable. However, their mechanical wear and the need for periodic maintenance due to the brushes and commutator can be a limitation.

What is a Brushless DC Motor and How Does it Work?

A brushless DC (BLDC) motor is an advanced type of electric motor that provides several advantages over its brushed counterparts. Unlike brushed motors, brushless motors do not rely on physical brushes and commutators to function. Instead, they use electronic controllers to manage the motor's operation, resulting in enhanced efficiency and performance.

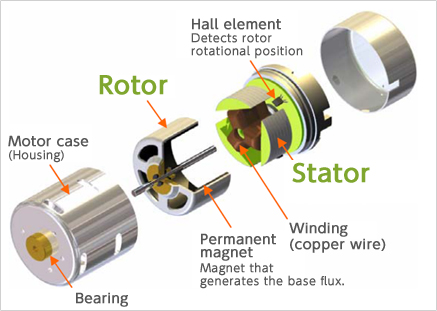

Key Components:

- Rotor: The rotor in a brushless DC motor is equipped with permanent magnets arranged around its circumference. These magnets create a magnetic field that interacts with the stator's field.

- Stator: The stator is the stationary part of the motor and is made up of windings or coils of wire. These windings generate a magnetic field when energized by an external power source.

- Electronic Controller: The electronic controller, often called an Electronic Speed Controller (ESC), replaces traditional motors' mechanical commutator and brushes. It provides precise electrical pulses to the stator windings, orchestrating the rotation of the rotor by creating a rotating magnetic field.

Source: nidec.com

How Does Brushless DC Motor Work?

In a brushless DC motor, the stator windings are energized in a sequence controlled by the ESC. This creates a rotating magnetic field that interacts with the permanent magnets on the rotor. The resulting magnetic forces cause the rotor to turn, producing mechanical motion.

Unlike brushed motors, which use mechanical commutation via brushes and commutators, brushless motors utilize electronic commutation. The ESC manages the commutation process by switching the current through the stator windings in precise sequences. This electronic control ensures smooth and efficient rotor rotation.

Source: a-m-c.com

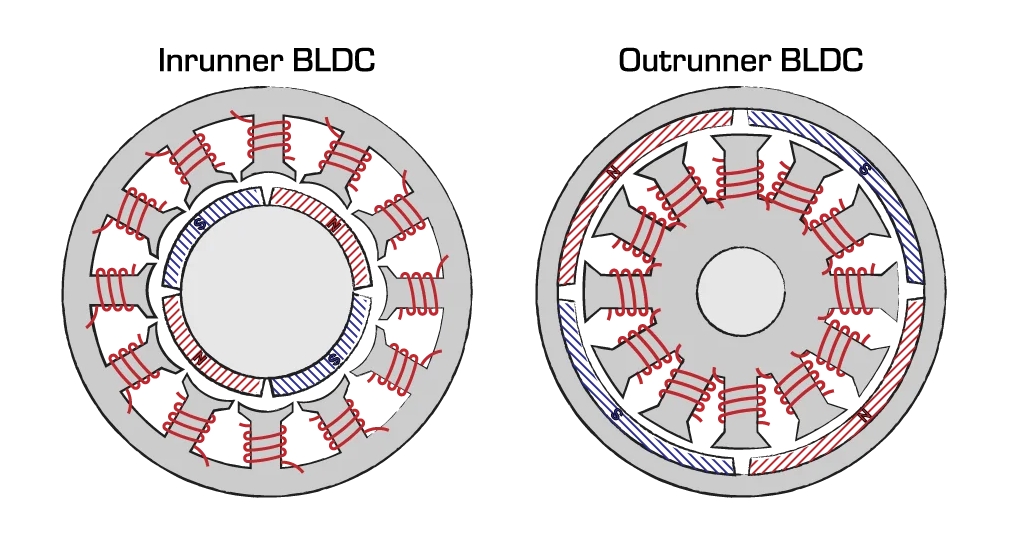

Brushless motors can have different configurations depending on the application. Most commonly, brushless motors are three-phase, meaning they have three sets of windings connected in a "star" or "delta" configuration. The rotor can be positioned inside the stator (inrunner) or outside it (outrunner). Higher pole counts and different magnetic configurations can enhance performance, though they may increase complexity.

Source: reddit.com

Brushless motors can be driven using various techniques. The simplest, trapezoidal commutation, involves connecting one phase to the ground, leaving another phase open, and applying a voltage to the remaining phase. This method can produce torque ripple, which is a variation in torque during rotation. For smoother performance, sine or 180-degree commutation can be used, where a sinusoidal current is applied to all three phases. This technique reduces torque ripple, acoustic noise, and vibration.

To control the motor effectively, the ESC needs to know the rotor's position relative to the stator. This is often achieved using Hall sensors mounted on the stator, which detect the magnetic field of the rotor. Advanced control methods, like Field Oriented Control (FOC), use algorithms to calculate the rotor's position based on current and other parameters, requiring more sophisticated processors.

Brushed vs. Brushless Motor: Pros and Cons

Brushed and brushless motors offer distinct advantages and disadvantages, impacting factors like flight time, performance, maintenance, and overall cost.

Let's delve into a detailed comparison to help you make an informed decision.

| Feature | Brushed Motor | Brushless Motor |

| Lifetime | Shorter | Longer |

| Maintenance Requirements | Regular brush replacement | Minimal |

| Speed & Acceleration | Lower | Higher |

| Efficiency Lower | Lower | Higher |

| Noise & Vibration Levels | Higher | Lower |

| Torque | Moderate | Higher |

| Weight & Size | Lighter | Heavier |

| Cost | Lower | Higher |

Lifetime

One of the biggest differences is how long each motor lasts. Brushed motors have brushes and a commutator, which wear out over time. Those carbon brushes are designed to be replaced periodically as part of a maintenance routine. The commutator, usually made of soft copper, also wears down eventually, leading to motor failure. On the other hand, brushless motors don't have these moving contacts, so they don't suffer from this kind of wear and tear. This means they generally have a much longer lifespan.

Speed and Acceleration

When it comes to speed and acceleration, brushless motors typically have the edge. Brushed motors can be limited by their brushes and commutator. At very high speeds, the brush contact can become erratic, and brush arcing increases, which isn't ideal. Plus, the iron cores in the rotor add rotational inertia, which limits how quickly the motor can speed up or slow down. Brushless motors can use powerful rare earth magnets, which minimize this inertia and allow for higher speeds and better acceleration.

Efficiency

Efficiency is another key area where these motors differ. Brushed motors lose some efficiency due to the friction and energy loss caused by the brushes. Brushless motors, lacking these friction points, are generally more efficient and lose less energy as heat.

Electrical Noise

Brushed motors can be noisy in terms of electrical interference. The brushes and commutator form an electrical switch that opens and closes as the motor turns, causing arcing. This generates significant electrical noise, which can interfere with sensitive circuits. While adding capacitors or RC snubbers can help, some noise is inevitable. Brushless motors, on the other hand, don't have this issue, making them quieter in terms of electrical noise.

Acoustic Noise & Torque Ripple

Acoustic noise and torque ripple are also considerations. Brushed motors are "hard switched," meaning the current moves abruptly from one winding to another. This creates torque ripple, which causes vibration and mechanical noise, especially at low speeds. Brushless motors can control the winding currents more smoothly, reducing torque ripple and mechanical noise. Depending on how the currents are controlled, they can be very quiet.

Cost

Finally, there's the matter of cost. Brushed motors are typically cheaper upfront because their technology is mature and manufacturing costs are low. However, they require more maintenance over time. Brushless motors are more expensive initially due to the need for sophisticated electronics, but their longer lifespan and lower maintenance needs can make them more cost-effective in the long run. Plus, as brushless motors become more popular and electronics costs drop, they’re becoming an increasingly attractive option.

FAQ

Do Brushless Motors Last Longer?

Yes, brushless motors generally last longer than brushed motors. The primary reason is that brushless motors do not have brushes and a commutator. In brushed motors, the brushes and commutator wear out over time due to the physical contact and friction, which leads to a shorter lifespan. Brushless motors, on the other hand, use electronic commutation to eliminate the need for brushes, resulting in significantly less wear and tear and thus a longer operating life.

Are Brushless Motors Quieter?

Yes, brushless motors are quieter than brushed motors. Since brushless motors do not have brushes that create friction and noise, they operate more smoothly and quietly. The lack of mechanical contact in brushless motors means there is less vibration and noise produced during operation.

How to Tell If a Motor is Brushed or Brushless?

To determine whether a motor is brushed or brushless, you can look for several key indicators:

- Physical Inspection: Brushed motors will have brushes and a commutator, which are visible if the motor casing is open. Brushless motors do not have these components.

- Electrical Noise: Brushed motors produce a distinct electrical noise due to brush arcing, while brushless motors are much quieter electrically.

- Performance: Brushless motors tend to have smoother operation, better efficiency, and higher speeds compared to brushed motors.

- Labeling: Often, manufacturers will label the motor explicitly as "brushless" (BLDC) or "brushed" (DC).

Brushless vs Coreless Motor?

Brushless motors and coreless motors are different in their construction and applications:

- Brushless Motor: Uses electronic commutation and does not have brushes. They are highly efficient, have long lifespans, and are commonly used in applications requiring high performance and reliability.

- Coreless Motor: A type of brushed motor that does not have an iron core in the rotor. The windings are self-supported, making the rotor much lighter and allowing for very high acceleration and deceleration rates. Coreless motors are often used in precision applications like small robotics and high-performance servos.

Brushless Servo Motor vs Brushless Motor?

A brushless servo motor is a type of brushless motor integrated with a feedback system (such as an encoder or resolver) and a controller to provide precise control of position, speed, and torque. They are commonly used in applications requiring precise motion control, such as robotics and CNC machinery.

- Brushless Motor: Refers to a motor without brushes, used primarily for high efficiency and long-life applications.

- Brushless Servo Motor: Includes all the benefits of a brushless motor, but with added feedback and control systems for precise motion applications.

What Type of Power Supply is Used for Brushless Motors?

Brushless motors typically use direct current (DC) power supplies. The power supply is often regulated to provide a constant voltage, and the motor’s controller (ESC - Electronic Speed Controller) converts this DC power into a three-phase AC signal to drive the motor. The voltage and current ratings of the power supply depend on the specifications of the motor and its application.